Why Clear and Bright Oil Samples are Not Good Enough

Before joining Noria as a technical consultant, I served in the U.S. Navy where I was stationed aboard the USS Saratoga and assigned to the oil lab. Prior to placing equipment into operation onboard the ship, we would draw an oil sample and conduct a visual analysis. If the sample was “clear and bright,” it was considered acceptable, and the equipment was placed into service. I now know that using the “clear and bright” standard is not nearly good enough. Particles that cause the majority of damage in equipment are smaller than can be seen with the naked eye, and lube oils can contain up to 0.1 percent water and still be “bright.” Keep in mind that at 0.1 percent water, 75 percent of the bearing’s life may have been lost.

“Lubricants must be maintained at specified standards of purity and at designed pressures and temperatures. Without proper lubrication, many units of shipboard machinery would grind to a screeching halt.”

Note the phrase “specified standards of purity.” Prior to starting a piece of equipment, one of the requirements is to draw an oil sample. This sample is sent to the shipboard oil lab for analysis. According to the Machinist Mate 1 & C, the procedure is as follows:

“The visual test must meet the clear and bright criteria. Clear refers to the lack of particulate matter in the sample. Particulate matter cannot cover more than one-quarter of the bottom of the sample bottle. The bright criteria refer to the lack of free water in the sample. Entrained water can dull the lube oil sample. If the sample is dull, try to read a PMS card through the sample. If you can read the PMS card, it passes this test. If it does not pass the visual test, you need to run a BS&W test. Be careful of entrained air that may dull the sample. If you are unsure whether air or water is the cause of the dullness, let the sample settle a few minutes. Air will clear to the top of the sample; water will settle to the bottom.”

If the oil sample contains particles longer than 1/8 inch along any axis or if visible sediment is noted, the procedure is to let the sample bottle sit for 10 minutes and then lay it on its side for 10 minutes or until all visible sediment has settled to the bottom. If this results in a solid line, a bottom sediment and water (BS&W) test is required. The BS&W test involves spinning 100 milliliters of the oil sample at 1,500 revolutions per minute for 30 minutes and then recording the results. Generally, results of less than 0.1 percent by volume are acceptable.

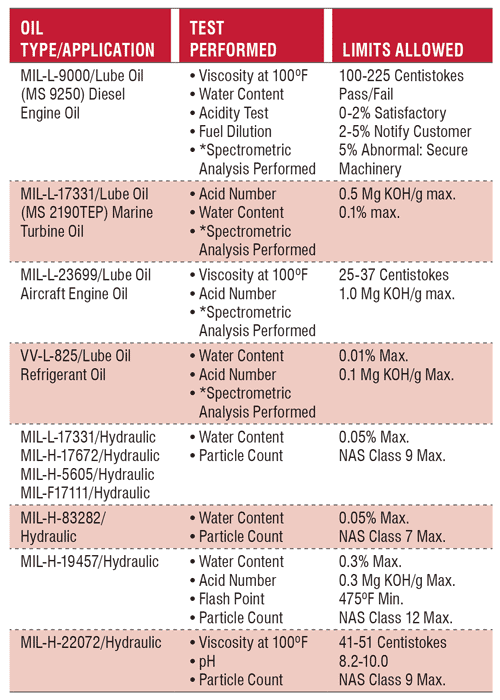

![]() Samples are sent periodically to a Navy oil analysis program laboratory for testing. The test slate will be dependent on the type of oil and the associated equipment class. The table above shows the test slate based on fluid and application types.

Samples are sent periodically to a Navy oil analysis program laboratory for testing. The test slate will be dependent on the type of oil and the associated equipment class. The table above shows the test slate based on fluid and application types.

For oils designated for equipment lubrication, a spectrometric analysis is conducted to track wear metal concentrations for trending and troubleshooting. Among the metals that are tested for include iron, nickel, sodium, lead, silver, phosphorus, copper, tin, zinc, chromium, silicon, calcium, aluminum, boron and barium. The National Aerospace Standard (NAS) classification reference is to the NAS 1638 standard, which was used to indicate particle counts. It has been discontinued and replaced with SAE AS4059E.

![]()

The NAS 1638 Contamination Classification System, which has been

discontinued and replaced with SAE AS4059E

Suffice it to say, it would be nearly impossible to see the particles that are doing the damage. Particles in the size range of the working clearance cause the most damage. Several of the larger pieces of marine equipment use journal bearings, so to a certain degree they are designed to be more forgiving of the smaller, submicron particles. However, in the case of rolling-element bearings, it is a different story. As previously stated, the lubricant film in rolling-element bearings is usually less than 1 micron.

According to SKF, the cleaner the lubricant, the longer bearings will last. In fact, the bearing company has gone so far as to state, “Bearings can have an infinite life when particles larger than the lubricant film are removed.”

SKF has conducted case studies and determined that roughly 70 percent of bearing failures are due in part to contamination. Similar studies show the benefits of controlling particle contamination. For instance, Nippon Steel was rewarded for its contamination control efforts with a nearly 76-percent reduction in pump replacement frequency, a 75-percent reduction in oil consumption, an 80-percent reduction in hydraulic repairs and a 50-percent reduction in bearing purchases. Likewise, after BHP Billiton improved filtration at one of its mills, production increased nearly 3.5 times. These are just a few examples of the benefits to be gained from controlling particle contamination.

“Bright” refers to the presence of water. Whoever made the statement that oil and water do not mix was just plain wrong. Nearly all oils have a certain quantity of dissolved water, and this dissolved water will not be evident by conducting a visual test. Oil will contain a quantity of water up to the saturation point and still appear clear.

According to SKF, “The presence of water in lubricating oils can shorten bearing life down to 1 percent or less, depending on the quantity present.”

![]() Oil can actually carry up to 2,000 parts per million of dissolved water before reaching its saturation point and beginning to appear cloudy.

Oil can actually carry up to 2,000 parts per million of dissolved water before reaching its saturation point and beginning to appear cloudy.

In his Machinery Lubrication article on how water causes bearing failure, Jim Fitch explained several modes of failure caused by water in oil. Among these are hydrogen-induced fractures, corrosion, oxidation, additive depletion, oil flow restrictions, aeration and foam, impaired film strength, and microbial contamination. A few of these modes are less obvious as to how they operate than others.

![]() In regard to impaired film strength, lubricating oils have a unique property known as the pressure-viscosity coefficient. Simply put, the higher the pressure, the higher the viscosity. The pressure in the load zones for rolling-element bearings is often in excess of 500,000 psi. This causes oil to almost become a solid, and it will maintain the separation between the rolling element and the raceway. The viscosity of water is one centistoke, and regardless of pressure, it stays essentially at one centistoke. Therefore, water will not be sufficient for maintaining the separation between the rolling element and the raceway.

In regard to impaired film strength, lubricating oils have a unique property known as the pressure-viscosity coefficient. Simply put, the higher the pressure, the higher the viscosity. The pressure in the load zones for rolling-element bearings is often in excess of 500,000 psi. This causes oil to almost become a solid, and it will maintain the separation between the rolling element and the raceway. The viscosity of water is one centistoke, and regardless of pressure, it stays essentially at one centistoke. Therefore, water will not be sufficient for maintaining the separation between the rolling element and the raceway.

It should now be readily apparent that it is not a sound practice to simply utilize the clear and bright criteria for determining whether oil is acceptable to use or for deciding whether equipment can be placed into service.

As far as I know, the Navy currently has no means of tracking the number of bearing failures it experiences over the course of a year. It would be interesting to see these statistics and the associated costs. If your organization is using the same methodology as the U.S. Navy, you likely are losing a large amount of money every year.

Case Study: USS San Antonio

The USS San Antonio was commissioned on Jan. 14, 2006. Shortly after being placed into service, the ship began to develop serious mechanical issues with its main propulsion diesel engines. The failures were the result of several factors, which were not all contamination-related. The Navy conducted an investigation into the causes of the engine failures. Several issues were discovered, with a good number of them resulting from poor contamination control. In the investigation’s report, it was noted that the lube oil service system design used muslin bags and that particles smaller than 25 microns would pass through the filters. During inspections of the engine oil sumps, welding slag, paint chips, inorganic fibers and free water were found. It was also reported that the system configuration allowed contaminants to recirculate through the pump. These contaminants would be macerated until they were able to pass through the filter.Oil Analysis in the Navy

The following excerpt is from the Navy’s Machinist Mate 3 & 2, which is the advancement training guide for steam plant operators, heating and air conditioning technicians, and ship oil kings:“Lubricants must be maintained at specified standards of purity and at designed pressures and temperatures. Without proper lubrication, many units of shipboard machinery would grind to a screeching halt.”

Note the phrase “specified standards of purity.” Prior to starting a piece of equipment, one of the requirements is to draw an oil sample. This sample is sent to the shipboard oil lab for analysis. According to the Machinist Mate 1 & C, the procedure is as follows:

“The visual test must meet the clear and bright criteria. Clear refers to the lack of particulate matter in the sample. Particulate matter cannot cover more than one-quarter of the bottom of the sample bottle. The bright criteria refer to the lack of free water in the sample. Entrained water can dull the lube oil sample. If the sample is dull, try to read a PMS card through the sample. If you can read the PMS card, it passes this test. If it does not pass the visual test, you need to run a BS&W test. Be careful of entrained air that may dull the sample. If you are unsure whether air or water is the cause of the dullness, let the sample settle a few minutes. Air will clear to the top of the sample; water will settle to the bottom.”

If the oil sample contains particles longer than 1/8 inch along any axis or if visible sediment is noted, the procedure is to let the sample bottle sit for 10 minutes and then lay it on its side for 10 minutes or until all visible sediment has settled to the bottom. If this results in a solid line, a bottom sediment and water (BS&W) test is required. The BS&W test involves spinning 100 milliliters of the oil sample at 1,500 revolutions per minute for 30 minutes and then recording the results. Generally, results of less than 0.1 percent by volume are acceptable.

For oils designated for equipment lubrication, a spectrometric analysis is conducted to track wear metal concentrations for trending and troubleshooting. Among the metals that are tested for include iron, nickel, sodium, lead, silver, phosphorus, copper, tin, zinc, chromium, silicon, calcium, aluminum, boron and barium. The National Aerospace Standard (NAS) classification reference is to the NAS 1638 standard, which was used to indicate particle counts. It has been discontinued and replaced with SAE AS4059E.

The NAS 1638 Contamination Classification System, which has been

discontinued and replaced with SAE AS4059E

Inherent Problems

The problems associated with using clear and bright as acceptance criteria for lubricants in operating machinery should be fairly obvious. “Clear” refers to the lack of particles, which are generally measured in microns. One micron is 39 millionths of an inch. The human eye can see particles down to the 40-micron range. A human hair is between 30 and 120 microns. The oil film on a journal bearing runs from 5 to 200 microns, but on rolling-element bearings, it is usually less than 1 micron. The table below offers a comparison of clearances for various components.Suffice it to say, it would be nearly impossible to see the particles that are doing the damage. Particles in the size range of the working clearance cause the most damage. Several of the larger pieces of marine equipment use journal bearings, so to a certain degree they are designed to be more forgiving of the smaller, submicron particles. However, in the case of rolling-element bearings, it is a different story. As previously stated, the lubricant film in rolling-element bearings is usually less than 1 micron.

According to SKF, the cleaner the lubricant, the longer bearings will last. In fact, the bearing company has gone so far as to state, “Bearings can have an infinite life when particles larger than the lubricant film are removed.”

SKF has conducted case studies and determined that roughly 70 percent of bearing failures are due in part to contamination. Similar studies show the benefits of controlling particle contamination. For instance, Nippon Steel was rewarded for its contamination control efforts with a nearly 76-percent reduction in pump replacement frequency, a 75-percent reduction in oil consumption, an 80-percent reduction in hydraulic repairs and a 50-percent reduction in bearing purchases. Likewise, after BHP Billiton improved filtration at one of its mills, production increased nearly 3.5 times. These are just a few examples of the benefits to be gained from controlling particle contamination.

“Bright” refers to the presence of water. Whoever made the statement that oil and water do not mix was just plain wrong. Nearly all oils have a certain quantity of dissolved water, and this dissolved water will not be evident by conducting a visual test. Oil will contain a quantity of water up to the saturation point and still appear clear.

According to SKF, “The presence of water in lubricating oils can shorten bearing life down to 1 percent or less, depending on the quantity present.”

In his Machinery Lubrication article on how water causes bearing failure, Jim Fitch explained several modes of failure caused by water in oil. Among these are hydrogen-induced fractures, corrosion, oxidation, additive depletion, oil flow restrictions, aeration and foam, impaired film strength, and microbial contamination. A few of these modes are less obvious as to how they operate than others.

It should now be readily apparent that it is not a sound practice to simply utilize the clear and bright criteria for determining whether oil is acceptable to use or for deciding whether equipment can be placed into service.

As far as I know, the Navy currently has no means of tracking the number of bearing failures it experiences over the course of a year. It would be interesting to see these statistics and the associated costs. If your organization is using the same methodology as the U.S. Navy, you likely are losing a large amount of money every year.