Pretreatment

Pretreatment Selection

1. Remove suspended solids.

2. Control calcium scaling.

* Antiscalant Injection

* Softening

* pH Adjustment (Acid Injection)

3. Other treatment as dictated by water analysis and desired recovery.

| Particulate | 10 to 25 micron cartridge filter. Sand or diatomaceous earth filter (Optional) |

| pH correction | Acid addition to lower pH to about 6. Membrane hydrolysis function of pH |

| Calcium Carbonate | pH adjustment prevents precipitation |

| Calcium Sulfate | Precipitation inhibited with scale inhibitors |

| Iron & Manganese | Soluble state no problem, but dander is oxidation to insoluble form at or near membrane. Oxidation, reduction, scale inhibitor possible methods |

| Colloids | Coagulation/Flocculation; Ultrafiltration |

| Organic Deposits | Filtration, Activated Carbon, Polyelectrolytes |

| Microbiological Organisms | Chlorination |

| Silica | Dependent on form, soluble, crystalline amorphous |

| Temperature | Product flux µ temperature; 1 to 1.5% per degree |

Pretreatment Techniques

| Feed Water Characteristics | Potential | Treatment |

| Turbidity (Suspended solids) | Forms Deposits in lines and equipment | Coagulation, settling, filtration |

| Color | Stains and causes foaming | Coagulation, filtration absorption |

| Odor (see dissolved gases) | Chlorination, Absorption | |

| Taste | Chlorination, Absorption | |

| Chemical Characteristics | Potential | Treatment |

| Hardness (Ca and Mg salts) | Forms Scale | pH, softening, conversion control |

| Minerals (Na, K, CI, SO4, HCO3) | Contribute to TDS | RO |

| Mn++ | Forms Deposits | Oxidation |

| Fe++ | Upon Oxidation | Filtration |

| Silica | Forms Scale | Lime softening process |

| Gases (O2 , H2 S, CO2 , NH3) | Cause Corrosion | Aeration Degasification |

| Biological Characteristics | Potential | Treatment |

| Bacteria | Forms organic | Chlorination |

| Algae | Deposits | UV Irradiation |

| Viruses |

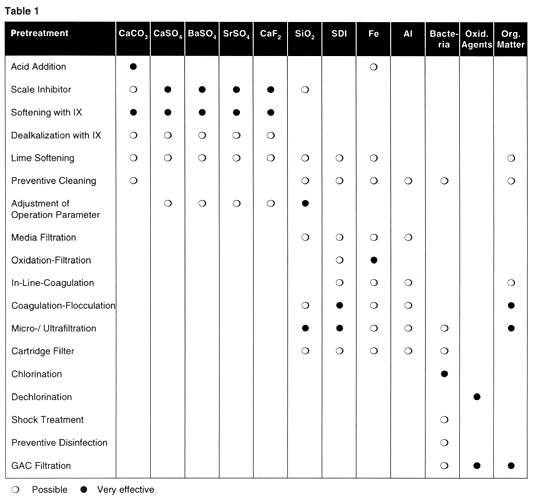

Summary of Pretreatment Options

This table summarizes the pretreatment options when specific risks for scaling and fouling are present. It is a quick reference for "possible" and "very effective".

Dechlorination

- Sodium Bisulfite (Na H SO3)

-10% Solution

-3 Lbs. of Na H SO3 per lb. of Cl2

- Activated Carbon

-1 million PPM gallons per cubic ft.

- Solution life of Sodium Bisulfite

SODIUM BISULFITE SOLUTION WEIGHT % | MAXIMUM SOLUTION LIFE |

2 | 3 Days |

10 | 1 Week |

20 | 1 Month |

30 | 6 Months |

Activated Carbon

- 1 cubic foot of Carbon will remove 1 ppm of Chlorine from 1 million gallons of water

- Design Flow Rate

-Chlorine 15 gpm/ft2

-Organics 6 gpm/ft2

Removal of Suspended Solids

| Technique | Equipment Options |

| Gravity Separation | Primary Sedimentation Secondary Sedimentation Chemical Sedimentation Flotation Clarification Settler |

| Physical Straining Process | Screening Diatomaceous Earth Filtration Ultrafiltration |

| Granular Media Filtration | Upflow Sand Filters Downflow Sand Filters Green Sand Filters Multi Media Filters Special Design Filters |

Granular-Media Deep-Bed Filtration

Table V. Minimum Fluidization Velocities for Various Uniform-Sized Media

(Observed Empirically)9

Between U.S. Std. Sieves

| Passing | Mm | Retained | Size | Mean Flow Rate to Achieve 10% | ||

| (mm) | Expansion at 25°C, gpm/ft2 | |||||

| Coal | Sand | Garnet | ||||

7 | 2.830 | 8 | 2.59 | 37.0 | ||

8 | 2.380 | 10 | 2.18 | 30.0 | ||

10 | 2.000 | 12 | 1.84 | 24.0 | 41.0 | |

12 | 1.680 | 14 | 1.54 | 20.0 | 33.0 | |

14 | 1.410 | 16 | 1.30 | 15.7 | 27.0 | 49.0 |

16 | 1.190 | 18 | 1.09 | 12.5 | 21.0 | 40.0 |

18 | 1.000 | 20 | 0.92 | 9.9 | 16.4 | 32.0 |

20 | 0.841 | 25 | 0.78 | 8.4 | 12.6 | 27.0 |

25 | 0.707 | 30 | .65 | 7.0 | 9.0 | 22.0 |

30 | 0.595 | 35 | 0.55 | 6.3 | 18.0 | |

35 | 0.500 | 40 | 0.46 | 5.4 | 13.7 | |

40 | 0.420 | 45 | 0.38 | 4.0 | 11.3 | |

50 | 0.297 | 60 (.25mm) | 0.27 | 6.3 | ||

Specify Gravity | 1.7 | 2.65 | 4.1 | |||

Table VI. Temperature Correction: Approximate Correction Factors to be Applied for Temperatures Other Than 25°C

Temperature (°C) | Multiply the 25°C Value by |

30 | 1.09 |

25 | 1.00 |

20 | 0.91 |

15 | 0.83 |

10 | 0.75 |

5 | 0.68 |

Typical Pressure Filter Media Beds For RO Pretreatment

A. SAND FILTERS

Top Layer -12” to 24” fine sand -0.45 to 0.6 mm e.s.

Middle Layer -6” to 12” coarse sand -0.8 to 1.2 mm e.s.

Bottom Layer -4” find gravel -1/4” to 1/8” diam.

B. DUAL - MEDIA FILTERS

Top Layer -6” to 24” No. 1 anthrafilt -0.65 to 0.76 mm e.s.

Layer -12” to 18” fine sand -0.45 to 0.6 mm e.s.

Layer -6” coarse sand -0.8 to 1.2 mm e.s.

Bottom Layer -4” fine gravel -1/4” to 1/8” diam.

C. MANGANESE ZEOLITE FILTERS

Top Layer -0 to 6” No. 1 anthrafilt -0.65 to 0.76 mm e.s.

Layer -12” to 18” manganese zeolite -0.27 to 0.37 mm e.s.

Layer -4” to 6” fine sand -0.45 to 0.6 mm e.s.

Layer -0 to 6” coarse sand -0.8 to 1.2 mm e.s.

Bottom Layer -4” fine gravel -1/4” to 1/8” diam

NOTE: Bed depths will depend on available height of pressure filter and at least 50% of bed depth should be allowed as free board for bed expansion.

Deep Bed Filtration - Design Recommendations

DUAL MEDIA

Recommended Depth:

Coal 18” - 24”

Sand 15” - 18”

FILTRATION RATE

5 Gallons/Minute/Square Foot Dual Media

15 Gallons/Minute/Square Foot Multi Media