Waste Reduction and Raw material conservation are the most important functions in Waste Management – Saves Environment and Money:

A. Introduction - Waste management has various functions; they are: collection, transport, processing (waste treatment), recycling or disposal of waste materials; usually produced by human activity, in an effort to reduce their effect on human health or local aesthetics or amenity. A sub-focus of waste management, in recent decades, has been to reduce waste materials’ effect on the natural world and environment by conserving raw materials used and to recover resources from wastes, i.e., recycle of wastes. Waste management can involve solid, liquid or gaseous substances with different methods and fields of expertise for each.

In fact, generation of waste in any industry is a result of using materials inefficiently. It costs your business money. The costs of wastes are twofold: first you fail to gain the desired benefits by using more raw materials and second, you also have to pay disposal costs for wastes. Apart, environment gets dirtier causing lot of air, water pollution and other related nuisances.

Waste is also the inefficient use of utilities such as electricity, water, and fuel, which are often considered unavoidable overheads. The costs of these wastes are generally underestimated by managers. It is important to realize that the cost of waste is not only the cost of waste disposal, but also other costs such as:

* Disposal cost

* Inefficient energy use cost

* Purchase cost of wasted raw material

* Production cost for the waste material

* Management time spent on waste material

* Lost revenue for what could have been a product instead of waste

* Potential liabilities due to waste.

a. By reducing waste, you can automatically make your processes more efficient and more competitive. The benefits of operating your business more efficiently are clear – including reduced overhead costs, savings in time and money and increased competitiveness. Better economy is achieved as you save additional costs for maintaining pollution free environment.

Although you can sometimes use waste as a resource and save money, it is more efficient to reduce waste at the point of origination. Waste activities such as recycling and recovery use energy so the priority should be to reduce waste in the first place. Businesses that take a strategic approach to minimizing waste are likely to save the most money. Experience in many countries suggests that businesses across a range of industries can save about 10 per cent of turnover by employing waste minimization techniques.

b. Immediate cost-savings can be achieved by:

(i) Reviewing your activities and processes and making simple changes such as printing or photocopying on both sides of the paper;

(ii) Designing packaging so that it can be reused;

(iii) Reusing any waste you produce until it no longer has any value and then recycling the materials.

Customers, employees and potential investors are all becoming more aware of environmental responsibility and failure to take action could affect your business.

c. You face rising energy and waste disposal costs, increased legal obligations and higher stakeholder expectations. In some industries, producers now have ultimate responsibility for the disposal of their products, not just their creation. Adopting a waste strategy means that you will be better prepared for any new legislation for reduction as well as for better disposal of your products (finished goods and wastes).

The penalties for failing to manage environmental risks properly can also be substantial. You could experience damage to your reputation, disruption to your business or financial penalties.

“Resource productivity” means extracting the most value from resources, making the best use of renewable resources and minimizing waste produced. It has the potential to drive down costs by reducing waste and pollution and will create opportunities for growth through process and product innovation.

B. Source Reduction of waste – Stopping waste before it starts – way to enhance environmental cleanliness:

Thus, waste minimisation can be defined as “systematically reducing waste at source”. It means:

* Prevention and/or reduction of waste generated

* Efficient use of raw materials and packaging

* Efficient use of fuel, electricity and water

* Improving the quality of waste generated to facilitate recycling and/or reduce hazard

* Encouraging re-use, recycling and recovery.

Source reduction, also known as waste prevention or pollution prevention, is the elimination of waste before it is created. Source reduction is decreasing the amount of materials or energy used during the manufacturing or distribution of products and packages. It basically involves the design, manufacture, purchase or use of materials and products to reduce the amount or toxicity of what is thrown away. Source reduction means stopping waste before it happens.

Because it stops waste before it starts, source reduction is the top solid waste priority of environmental protection agencies of many of the developed countries. These innovations conserve resources and reduce packaging waste, while continuing to provide performance, value and convenience to the consumer.

Source reduction is not the same as recycling. Recycling is collecting already used materials and making them into another product. Recycling begins at the end of a product’s life, while source reduction first takes place when the product and its packaging are being designed. In fact, the best way to think about source reduction and recycling is as complementary activities – combined, source reduction and recycling have a significant impact on preventing solid waste and saving resources.

a. Source Reduction Techniques:

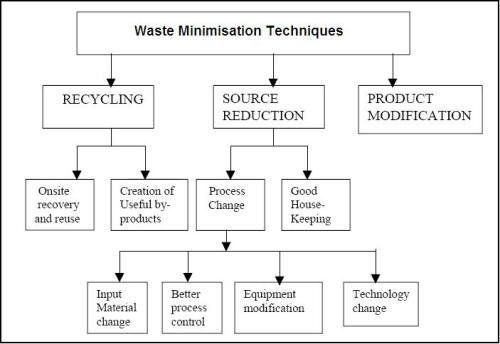

Four techniques of waste minimisation are briefly discussed below:

1) Good Housekeeping-Systems to prevent leakages & spillages through preventive maintenance schedules and routine equipment inspections. Also, well-written working instructions, supervision, awareness and regular training of workforce would facilitate good housekeeping.

2) Process Change - Under this head, four techniques are covered:

(i) Input Material Change- Substitution of input materials by eco-friendly (non-toxic or less toxic than existing and renewable) material preferably having longer service time.

(ii) Better Process Control - Modifications of the working procedures, machine-operating instructions and process record keeping in order to run the processes at higher efficiency and with lower waste generation and emissions.

(iii) Equipment Modification - Modification of existing production equipment and utilities, for instance, by the addition of measuring and controlling devices, in order to run the processes at higher efficiency and lower waste and emission generation rates.

(iv) Technology Change - Replacement of the technology, processing sequence and/or synthesis route, in order to minimise waste and emission generation during production.

3) Recycling -

i) On-site Recovery and Reuse - Reuse of wasted materials in the same process or for another useful application within the industry.

ii) Production of Useful by-product- Modification of the waste generation process in order to transform the wasted material into a material that can be reused or recycled for another application within or outside the company.

4) Product Modification – Characteristics of the product can be modified to minimise the environmental impacts of its production or those of the product itself during or after its use (disposal).

b.Importance of source reduction of waste:

(i) Source reduction conserves raw material and energy resources. Smaller packages and concentrated products typically use fewer materials and less energy to manufacture and transport.

(ii) Source reduction reduces releases to air, land and water. For example, it takes less fuel to transport lighter weight materials.

(iii) Source reduction cuts back on what has to be thrown away. That helps keep solid waste disposal costs down, which is good for municipal budgets and consumers.

(iv) Source-reduced products take up less space, and are more efficient and easier to use.

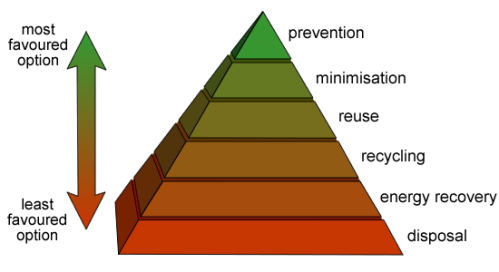

c.Source reduction is the highest goal in the solid waste management hierarchy -Reduce, Reuse, Recycle: As explained above, by itself, recycling does not address the issue of wasteful product use. When recycling is coupled with source reduction, however, wasteful purchase and use of products is minimized. Whenever possible, reduce or reuse first, then recycle. The practice of source reduction benefits the environment through reduced energy consumption and pollution, conservation of natural resources, and extension of valuable landfill space. It can also have economic benefits by reducing costs associated with transportation, disposal or recycling of waste. Plus, source reduction can save you money every day. Everyone can participate in source reduction. REDUCE OR REUSE FIRST, THEN RECYCLE.

C. Waste reduction in production process and reduction in use of raw materials gives significant effect on profitability and promoting cleaner environment:

Waste arising out from production processes can have a significant effect on your profitability. The challenge is to reduce this waste without undermining the effectiveness of the process. The reduction of waste generation also mitigates the wastes disposal and recycling problem; thereby improving the environment standard.

a. During the production process some typical problems include the excessive consumption of energy or raw materials, losses in the production process itself, rejection at the inspection stage and failure when the customer is using the end product. In order to reduce waste you have to be very much conversant with the process. To know where waste is arising, you need to understand your processes and technology used. To do this, you could produce a flowchart of your operations. You can then discuss the process with your employees and get their feedback on where waste is occurring, and what you can do to reduce it. This approach helps you focus on the most important areas, with more detailed analysis of the operation at various segments of the process, if necessary.

b. Common things you might do to improve the efficiency of production processes and reduce waste include:

(i) reusing rinse water in cooling systems;

(ii) regularly checking that equipment is correctly calibrated;

(iii) reducing unnecessary stoppages in the production line;

(iv) upgrading or replacing old equipment;

(v) minimizing spills or leaks;

(vi) using sealed systems to allow all the waste to be collected in one place, without leakage, so that as much waste as possible can be reused, recycled or disposed of correctly.

c. An effective waste minimization program scrutinizes the whole business from suppliers to product design, production practices to disposal. It will also enable you to minimize the different input resources, including water and energy, chemicals and solvents, and paper and electrical equipment.

Preventing waste from occurring in the first place is the most efficient solution. Constant monitoring of your production processes and preventive maintenance can ensure waste is avoided before it occurs.

d. Reduce your use of raw materials at the fullest extent – Given current levels of consumption; recycling rubbish isn’t sufficient to tackle the amount and type of waste produced. Waste needs to be designed out of the system at source, and what cannot be designed out should be reused.

(i) Developing better “closed loop systems” – where waste is treated as a resource – eliminates the need for unused resources and waste disposal.

(ii) If you’re a manufacturer, using raw materials more efficiently can bring significant cost savings and environmental benefits. To do this, you should look at all aspects of your production process, including transportation and warehousing.

(iii)Try to ensure you don’t over-order materials for one-off or bespoke jobs. Check how you handle and store raw materials. Even failing to empty all bags and containers properly could lead to significant amounts of waste.

(iv) Look carefully at the waste you’re disposing of. Could any of it be reprocessed and put back into the production process? Could it be reused for another purpose? For example, packaging from suppliers can be reused to transport your own products. Also, waste water from manufacturing processes could be reused for low grade purposes.

(v) Another important area to consider is product design. Are there ways of designing your product so that it uses fewer raw materials? Try to use materials that have already been recycled or that are easier to recycle.

(vi) Issues such as raw material use, waste production, energy consumption and emissions to the atmosphere should be considered at each stage of the product lifecycle.

D. Suggestions for better waste management:

You can help reduce waste at home by learning basic waste-saving habits. You can buy products that come in concentrated forms or products that use minimal packaging. And you can reuse, repair, recycle, or compost products that would otherwise be thrown away.

REDUCE

* Buy the largest size package and products that do more than one thing; for example, shampoos that include conditioners.

* Buy concentrated products or compact packages, such as frozen juices and fabric softeners you mix with water at home.

* Look for products with minimal packaging. You will be using fewer natural resources, and you will have less to throw away.

* When you mow your lawn, leave grass clippings on the ground instead of bagging them. Grass clipping decompose quickly, adding nutrients to the soil.

REUSE

* Buy reusable products such as rechargeable batteries.

* Pass on magazines, catalogues, and books to neighbors, hospitals, schools, and nursing homes.

* Reuse plastic or glass containers for food storage, nails, and so on.

* Reuse plastic shopping bags, boxes, and lumber.

* Reuse wrapping paper, gift bags, and bows. Use the Sunday comics for wrapping children’s birthday presents.

REPAIR

* Try to repair before you consider replacement of lawn mowers, tools, vacuum cleaners, and TVs.

* Donate items you can’t repair to local charities or vocational schools.

* Keep appliances in good working order. Properly maintained appliances are less likely to wear out or break and will not have to be replaced as frequently.

RECYCLE

* Shop for items that are recyclable or are made from recycled materials.

* Recycle newspapers, plastics, glass, and cans.

* If a recycling program does not exist in your community, contact community officials to see if it would make sense to start one.

COMPOST

* Compost yard and kitchen waste. Compost makes an excellent fertilizer and improves the soil.

* If there’s no room for compost pile, offer compostable materials to community composting programs or garden projects near you.

E. Conclusion - The biggest challenges in waste reduction programme lies in sustaining the process. The enthusiasm of the implementing team wanes off with time. Such tragic ends should be avoided. Backing out from commitment, predominance of production at any cost, absence of rewards and appreciation, and shifting of priorities are some of the commonly encountered reasons, which one should check and avoid. Also monitoring and review of the implemented measures should be communicated to all employees in the industry so that it fans the desires for minimizing wastes.

WASTE REDUCTION, REUSE, AND RECYCLING ALLOW US TO USE FEWER RAW MATERIALS AND CONSERVE NATURAL RESOURCES, PRESERVING LANDFILL SPACE AND MINIMIZING ENERGY USE.

THE IMPACT IS DIFFICULT TO IGNORE.

References:

- http://environmentengineering.blogspot.com/2008/05/reduce-waste-to-save-environment-and.html

- http://environmentengineering.blogspot.com/2008/05/waste-reduction-in-production-process.html

- http://environmentengineering.blogspot.com/2008/05/source-reduction-of-waste-stopping.html

- http://www.portstephens.nsw.gov.au/environment/1278/66508.html

- http://www.admix.com/AudioCardLanding/rework.htm

- http://www.p2pays.org/ref/13/12872.htm

- http://www.o-r-a.co.uk/waste-auditing.html

- http://flgreenliving.com/blog/2008/08/08/waste-management-opens-new-recycling-facility/

- http://www.sustainable-development.veolia.com/en/Articles/Sheffield-waste/