Sustainable packaging, packaging waste reduction and development of biodegradable plastics for packaging – means to promote cleaner environment:

![pds_recycle pds_recycle]()

![pds_recycle_1 pds_recycle_1]()

![pds_pha pds_pha]()

(iv) These features can be seen in the structures of some degradable polymers that are already in use.

![pha pha]()

Packaging is used in business to contain and promote finished products for consumer sales and also to transport them to the point of sale safely. The function of packaging includes protecting products in shipping, offering consumers information, providing a branding billboard and giving us a way to carry things home. The most commonly used packaging materials are paper, fiberboard, plastic, glass, steel and aluminum.

A. High proportion of waste is actually packaging -

Innovative packaging design can mean that the amount of materials used is reduced and that all packaging can be reused or at least recycled. In other words, it is nothing but creating more ‘sustainable packaging’. Using the minimum and most efficient packaging will increase your competitiveness and save you money, as well as attracting environmentally-aware consumers.

Fortunately, everyone from the retail behemoth Wal-Mart to start-up companies and boutique design shops are beginning to look for ways to reduce the volume of stuff we throw away. However, even the most green-sympathetic designer will quickly find there are no easy answers or quick fixes when it comes to sustainable packaging. Even defining the term poses difficulties.

B. ‘What’s a sustainable package?’–

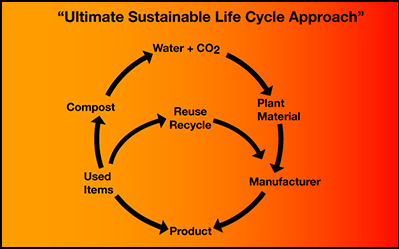

Now, the question becomes not how to do away with packaging, but how to use less of the less-harmful materials. To become more sustainable, designers must consider and improve each step along the entire product journey. Packaging, like any other design problem, will need to be rethought with a sustainable systems approach. Designers should expand and evolve creative processes to include strategies like

(a) optimizing material and energy resources;

(b) sourcing materials that are produced responsibly with environmental best practices, fair labor and trade;

(c) choosing materials that are nontoxic, bio-based and made from renewable resources; and

(d) designing for resources recovery or reintegration back into nature after end use.

C. Sustainability criteria for packaging -

1. Is beneficial, safe and healthy for individuals and communities throughout its lifecycle;

2. Meets market criteria for performance and cost;

3. Is sourced, manufactured, transported and recycled using renewable energy;

4. Maximizes the use of renewable or recycled source materials;

5. Is manufactured using clean production technologies and best practices?

6. Is made from materials healthy in all probable end-of-life scenarios;

7. Is physically designed to optimize materials and energy;

8. Is effectively recovered and utilized in biological and/or industrial cradle-to-cradle cycles.

D. The “5 Rs”of creation of sustainable package –

Designers dedicated to fostering environmental sustainability—offer some practical advices:

Restore by using materials and supporting firms that reduce or improve our natural capital;

Respect what we have by examining all the impacts that packaging may have;

Reduce the amount of materials, layers of packaging, weight of package, fuel used in transport, etc.;

Reuse something that’s already been made, and make your package easy and desirable to reuse; and

Recover the materials used through recycling, composting or reusing.

One of the most important and simple ways a designer can move beyond conventional packaging solutions is to consider alternative materials. PLA (polyactic acid) is fast becoming the favored alternative to plastic. PLA is made from renewable resources such as corn, and uses fewer fossil fuels and generates fewer greenhouse gases in its production than traditional plastics and some other polymers. PLA can be composted as well. Fortunately, other materials are also coming to commercial viability.

E. The increase in online shopping has meant a rise in goods being delivered direct to customers’ homes. This means that more packaging is needed to supply the goods. You can encourage customers to return your packaging to you for reuse by supplying them with a “freepost” return label.

F. Other ways of improving packaging use are:

(i) Using recycled materials where possible;

(ii) Designing the packaging using the least amount of materials necessary;

(iii) Reusing your own packaging to create new packaging or in other areas of your business.

G. Bio-degradable plastics for packaging – development and use are the key for improvement of environment:

There is growing concern about the excess use of plastics, particularly in packaging. In response to problems associated with plastic waste and its effect on the environment, there has been considerable interest in the development and production of biodegradable plastics.

a. At present, we make almost 100% of plastics of our requirement from oil and natural gas. Petroleum-based plastics are basically non-degradable. As concern grow about the potential bad effects of petroleum-based non-degradable plastics on the environment, the viability of petroleum-based plastics are in question. At the same time, the increased dependence on oil and gas imports due to manufacture of such petroleum-based products, make us think about the possible solution. In this respect, searching for suitable degradable polymers for various applications as per the need, have become very important aspect in today’s science and technological affair for research.

b. As per reports of various environment protection agencies, plastics alone account for more than 25% (by volume) of municipal waste generated. Plastic’s low density and slowness to decompose makes them a visible pollutant of public concern. Some of the techniques adopted for integrated waste management, which include recycling, source reduction of packaging materials, composting of degradable wastes, incineration etc., may help reduce waste disposal problem; but this will not solve the importation of petroleum products and problem with non-degradability of plastics. As per statistics, about 80% of post-consumer plastic waste is sent to landfill – degrading land masses and causing water pollution, 8% is incinerated – causing unwanted emission and only 7% is recycled. The situation is so acute in some countries of Europe of Japan that today few sites left that can be used for landfill. Since the main bulk of domestic waste is made up of plastics there is a great deal of interest in recycling plastics and in producing plastic materials that can be safely and easily disposed of in the environment.

c. The option to get rid of the adverse effects of non-degradable petroleum-based plastics may be to make bio-degradable plastics suitable for our various applications. Some of the manufacturers in developed countries have already developed some type of degradable plastics made from agricultural products such as corn, potato etc. In fact, bio-degradable plastics can be made from lactic acid. Lactic acid is produced (via starch fermentation) as a co-product of corn wet milling, which can be converted to polyactides (PLA). Alternatively, it can be produced using the starch from food wastes, cheese whey, fruit or grain sorghum.

d. The properties of the plastics changes as per the applications for which it is needed. Some plastics need to be durable like the parts in a car. Yet, there are many plastics that are only used once or have a limited life before being thrown into a landfill or incinerator. Plastics, unlike most organic polymers, are poorly degraded by microbes (although recently some genetically engineered microbes / bacteria have been invented to transform plastic waste into useful eco-friendly plastics – but it is still in research stage). Environmentally degradable polymers are one potential solution to replacing petroleum-based polymers. Potential uses for these polymers are plastics intended for one-time or limited use, for example those used as fast-food wrappers and water-soluble polymers in detergents and cleaners, and for use in the printing industry. Thus, an ideal degradable product would:

(i) Perform the intended task effectively;

(ii) Produce little or no side effects in any non-intended target;

(iii) Break down, along with any residues of its activity, over a reasonably short time scale;

(iv) Produce no harmful substances when it breaks down.

e. Waste disposal: The question now arises, how best to dispose of domestic wastes. The ways of disposing of waste and time required for degradation is very important factors in development of bio-degradable plastics. Current bio-degradable polymers are designed to degrade either biologically or chemically, depending on the disposal environment that they will encounter after use. Ideally, degradation pathways should ultimately lead to the bio conversion of the polymer into carbon dioxide (aerobic) or carbon dioxide/methane (anaerobic) and biomass. Environmental laws and regulations and consumer demands for environmentally friendly products are beginning to have an impact on the use of degradable polymers. As a result degradable polymers, when combined with other degradable plastics, will begin playing a crucial role in helping to solve our waste disposal problems and reducing petroleum imports.

f. Properties of bio-degradable polymers: These new polymers developed from agricultural products described above are truly degradable. These polymers may be used in many applications as well. Some are impervious to water, moisture etc., and retain their integrity during normal use, but readily degrade when they are kept in a biologically rich environment. The amazing part is the full biodegradability can occur only when these materials are disposed of properly in a composting site or landfill. Today, there are three major degradable polymers groups that are either entering the market or are positioned to enter the market. They are

(i) polyactides (PLA),

(ii) polyhydroxybutyrate (PHB) and

(iii) starch-based polymers.

g. Design for Bio-Degradation of Polymer: Following few points are given to attain bio-degradability.

(i) Some organic chemicals degrade only very slowly, and so the level in the environment can rise steadily. These are the persistent organic pollutants (or “POPs”).(ii) In contrast, all chemicals produced in nature are 100% degradable and understanding why this is the case is an important part of being able to design synthetic degradable materials.

(iii) For example, natural polymers such as carbohydrates, proteins and nucleic acids usually have oxygen or nitrogen atoms in the polymer backbone. If these atoms are included in synthetic polymers, the material is more easily degraded. A carbon-oxygen double bond (carbonyl group) absorbs light energy, and so can make a substance photodegradable.(iv) These features can be seen in the structures of some degradable polymers that are already in use.

h. Bio-degradable polymers are quite new. Only during last five years some bio-degradable polymers for applications have been in use in some of the developed world. Although they are degradable, the industry has not promoted them. One reason is these new polymers are higher priced than the commodity polymers typically in use in plastics applications. However, producers are currently working toward bringing down the price of degradable polymers by increasing production capacity and improving process technology.

i. Price competitiveness and future growth of bio-degradable polymers: The trend observed regarding bringing down the prices of degradable polymers in last five years is quite encouraging. In US, five years ago PLA and PHB sold for more than USD 25.00 per pound. Today PLA, depending on quantities, is between USD 1.50 and USD 3.00 per pound and PHB, in large quantities is near USD 4.00 per pound.

Though recent advances in production technology have helped lower prices of some degradable resins, prices are still higher than for petroleum-based plastics. This suggests that in the short term, companies making degradable polymers will continue to focus on niche markets. As production capacity increases it is expected that future prices to fall to roughly USD 1 per pound. Moreover, due to sharp increase in prices of petroleum-based plastics in recent time, the prices of bio-degradable polymers will become very much competitive soon.

j. Further, several factors, besides cost, will be important in determining the future growth of degradable polymers. One major obstacle is a lack of a composting infrastructure. Large-scale composting would provide the ideal disposable environment for spent degradable. Future legislation will depend not only on the environmental awareness of planners and politicians but also on their perceptions of how degradable polymers may affect the development of plastics recycling.

H. Bacteria that effectively transform plastic waste into a useful eco-friendly plastic -

In response to problems associated with plastic waste and its effect on the environment, there has been considerable interest in the development and production of biodegradable plastics. Innumerable amount of research have also been conducted world wide to find out ways to convert synthetic plastic waste into biodegradable and compostable material. Their effort was to isolate bacterium that can effectively convert a waste plastic product into safe, biodegradable product or to make safe and biodegradable plastic, which can be used safely for further manufacture of some product.

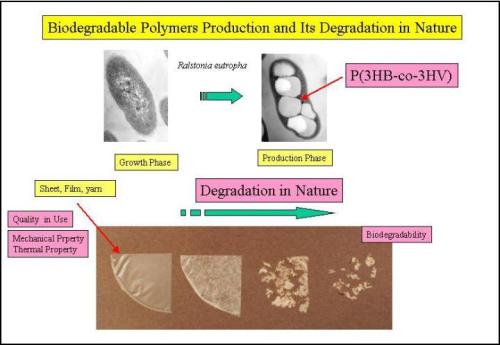

a. It has been observed that, chemicals called Polyhydroxyalkanoates (PHAs) are polyesters that accumulate as inclusions in a wide variety of bacteria. These bacterial polymers have properties ranging from stiff and brittle plastics to rubber-like materials. Because of their inherent biodegradability, PHAs are regarded as an attractive source of nonpolluting plastics and elastomers that can be used for specialty and commodity products. They were the first biodegradable polyesters to be utilised in plastics. These aliphatic polyesters naturally produced via a microbial process on sugar-based medium. The two main members of the PHA family are polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHV).

b. There is good news that, recently some European scientists have discovered a bacterial strain that uses styrene, a toxic byproduct of the polystyrene industry, as fuel to make Polyhydroxyalkanoate (PHA) – biodegradable plastic. The microbes, a special strain of the soil bacterium Pseudomonas putida, convert polystyrene foam — commonly known as Styrofoam — into PHA, a biodegradable plastic. This is among the first to investigate the possibility of converting a petroleum-based plastic waste into a reusable biodegradable form.

Researchers utilized pyrolysis, a process that transforms plastic waste materials by heating them in the absence of oxygen, to convert polystyrene — the key component of many disposable products — into styrene oil. The researchers then supplied this oil to Pseudomonas putida, a bacterium that can feed on styrene, which converted the oil into PHA. The process might also be used to convert other types of discarded plastics into PHA.

c. PHA has numerous applications in medicine and can be used to make plastic kitchenware, packaging film and other disposable items as well. This biodegradable plastic is resistant to hot liquids, greases and oils, and can have a long shelf life. The advantageous side of PHA is unlike polystyrene, it readily breaks down in soil, water, septic systems and backyard composts. In other words, it is biodegradable and compostable.

d. Worldwide, more than 14 million metric tons of polystyrene are produced annually, most of this ends up in landfills producing pollution. Thus, this system can help transform plastic waste into a useful eco-friendly plastic, significantly reducing the environmental impact of this ubiquitous, but difficult-to-recycle waste stream.

I. Conclusion: Fortunately, in developed world a new movement is working to make manufacturers more accountable by pushing them to stop producing anything that can’t be resold, recycled or reused. Designers have started increasingly recognizing that doing good for the planet is doing good for themselves.

References:

5. http://www.enviropak.com/Frames_Home/enviropakmain.ht