What is gas chromatography (GC)?

Gas Chromatography

Gas chromatography (GC) is based on the repeated partition or adsorption, between a mobile phase and a stationary phase, of components to be separated. The mobile phase is always a gas known as the carrier gas. The stationary phase can be either a solid or a liquid.

When the stationary phase is a solid then it is called gas-solid chromatography (GSC) or adsorption chromatography. The components of the injected sample are adsorbed on the solid and the principle of separation is based on the fact that the various components can be more or less strongly adsorbed by the adsorbent.

The solid stationary phases used in gas chromatography are materials such as silica gel, active carbon, aluminum oxide, molecular sieves.

When the stationary phase is a liquid then it is called gas-liquid chromatography(GLC) or partition chromatography. The components of the injected sample form different concentrations in the liquid stationary phase and in the gaseous mobile phase.

Like all chromatographic techniques, gas chromatography separates mixtures by taking advantage of their components differential distribution between two phases – one stationary and the other moving. The distinctive feature of gas chromatography is the use of a gas as the moving, or mobile, phase. It is usually called carrier gas. A sample of the mixture to be separated is introduced into this gas stream just before it encounters the stationary phase. The components of the injected sample – the sample may be a liquid or a gas- are separated by elution and detected as they emerge in the gas at the other end of the column (Fig. 1). They are distinguished by the different times which they take to pass through the colum – the retention times.

|

| Fig. 1: Block diagram of a gas chromatography system |

The hardware components used in typical GC systems include aninjector, a carrier gas, a column (stationary phase), an oven, a detector and a recorder or information processor (Figure 1). Several components have variable settings that can be used to optimize the analysis of different sample types.

A GC-MS analytical instrument is shown in the following video. A mass spectrometer is the detector in this case:

Which are the most common mobile phases in gas chromatography?

The most common mobile phases(carrier gases) for gas chromatography (GC) are He, H2 and N2 which have the advantage of being chemically inert toward both the sample and the stationary phase. However, other gases such as Ar and CO2 have also been used though much less frequently.

The choice of which carrier gas to use is often determined by the instrument’s detector.

The gases can be obtained from commercial air suppliers, conveniently compressed in cylinders and in a state of purity sufficient for most purposes.

What happens if the mobile phase gases are impure?

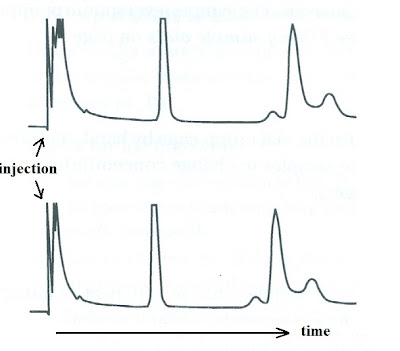

If the gases are impure then a very unstable and noisy baseline is observed in the chromatogram.

The commonest impurity is water, and drying the gas with an in-line molecular sieve trap is recommended.

Another impurity is oxygen which may cause oxidation of the stationary phase particularly in high temperatures. The stationary phases are usually organic, and the products of oxidation are usually volatile and cause a noisy, drifting baseline when they reach the detector. The column life will also be shortened and will not give good results.

The Injection System in Gas Chromatography – Sample Introduction

Sample introduction is of primary importance in gas chromatography. The performance of the sample introduction system is crucial for the overall chromatographic performance.

What volume of sample is injected to the gas chromatograph and how?

The sample volume injected is usually less than 1-2 μl of liquid or 5 cm3 of gas. Injection, is usually achieved by means of a syringe inserted through a self-sealing silicone rubber septum at the injection head.

|

| Fig. 2: Injection head of a gas chromatograph. Injection is achieved by means of a syringe inserted through a self-sealing silicone rubber septum at the green-colored injection port. |

However, there are a number of problems inherent in the use of syringes for injection, even when they are not damaged:

- Even the best syringes claim an accuracy of only 3%, and in unskilled hands, errors are much larger

- The needle may cut small pieces of rubber from the septum as it injects sample through it. These can block the needle and prevent the syringe filling the next time it is used. It may not be obvious of what happened.

- A fraction of the sample may get trapped in the rubber, to be released during subsequent injections. This can give rise to ghost peaks in the chromatogram.

- There may be selective loss of the more volatile components of the sample by evaporation from the tip of the needle.

There are also several problems with the splitting process since the split may not be homogeneous. This may be because there is a poor mixing with the carrier gas at the dilution stage or because the low relative molecular mass components diffuse toward the vent more rapidly than those of higher molecular mass.

In principle, there are four types of sample injection:

- Splitless injection

- Split injection

- Temperature-programmed injection

- On-column sample injection

When splitless injection is used?

This method is useful for very dilute solutions. When splitless injection is used, the column is overloaded with the solvent. For this reason, the temperature at the top of the column is kept low (10-20 ◦C below the boiling point of the solvent), so that the low-volatility components and the solvent condense. This condensation causes the components to be focused. The method is not recommended for volatile components, as these are eluted from the column with the solvent.

When split injection is used?

Split sampling was the first sample introduction system developed for capillary gas chromatography. In the split injection technique,only a part of the sample is delivered to the column. This method is used with capillary columns. The sample is injected into the carrier gas stream through a septum, vaporized in the vaporizing chamber, and then mixed with the carrier gas. The gas then is divided into two streams by means of an infinitely adjustable needle valve, which should be adjusted so that a very small proportion of the sample is delivered to the column. This method is used when concentrations in the sample are high because the capacity of a capillary column is low.

References

- D. Harvey, “Modern Analytical Chemistry”, McGraw-Hill Companies Inc., 2000

- “Gas Chromatography”, J. Willett, John Wiley &Sons, 1987

- “High Resolution Gas Chromatography”, K.J. Hyver, P. Sandra, 3rdEdition, 1989