INTRODUCTION The automobile industry has to address the following issues at all the stages of vehicle manufacture: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Since pollution is caused by various sources, it requires an integrated, multidisciplinary approach. The different sources of pollution have to be addressed simultaneously in order to stall widespread damage. THE PARAMETERS DETERMINING EMISSION FROM VEHICLES

While each one of the four factors mentioned above have direct environmental implications, the vehicle and fuel systems have to be addressed as a whole and jointly optimised in order to achieve significant reduction in emission. VEHICULAR TECHNOLOGY In India, the vehicle population is growing at rate of over 5% per annum and today the vehicle population is approximately 40 million. The vehicle mix is also unique to India in that there is a very high proportion of two wheelers (76%).History of Emission Norms in India The significant environmental implications of vehicles cannot be denied. The need to reduce vehicular pollution has led to emission control through regulations in conjunction with increasingly environment-friendly technologies.It was only in 1991 that the first stage emission norms came into force for petrol vehicles and in 1992 for diesel vehicles. From April 1995 mandatory fitment of catalytic converters in new petrol passenger cars sold in the four metros of Delhi, Calcutta, Mumbai and Chennai along with supply of Unleaded Petrol (ULP) was affected. Availability of ULP was further extended to 42 major cities and now it is available throughout the country. The emission reduction achieved from pre-89 levels is over 85% for petrol driven and 61% for diesel vehicles from 1991 levels. In the year 2000 passenger cars and commercial vehicles will be meeting Euro I equivalent India 2000 norms, while two wheelers will be meeting one of the tightest emission norms in the world. Euro II equivalent Bharat Stage II norms are in force from 2001 in 4 metros of Delhi, Mumbai, Chennai and Kolkata. Since India embarked on a formal emission control regime only in 1991, there is a gap in comparison with technologies available in the USA or Europe. Currently, we are behind Euro norms by few years, however, a beginning has been made, and emission norms are being aligned with Euro standards and vehicular technology is being accordingly upgraded. Vehicle manufactures are also working towards bridging the gap between Euro standards and Indian emission norms. FUEL TECHNOLOGY In India we are yet to address the vehicle and fuel system as a whole. It was in 1996 that the Ministry of Environment and Forests formally notified fuel specifications. Maximum limits for critical ingredients like Benzene level in petrol have been specified only recently and a limit of 5% m/m and 3% m/m has been set for petrol in the country and metroes respectively.In place of phase-wise upgradation of fuel specifications there appears to be a region-wise introduction of fuels of particular specifications. The high levels of pollution have necessitated eliminating leaded petrol, through out the country. To address the high pollution in 4 metro cities 0.05% sulphur petrol & diesel has been introduced since 2000-2001. The benzene content has been further reduced to 1% in Delhi and Mumbai. There is a need for a holistic approach so that upgradation in engine technology can be optimised for maximum environmental benefits. Other factors influencing emission from vehicles. INSPECTION & MAINTENANCE (I&M) OF IN-USE VEHICLES It has been estimated that at any point of time, new vehicle comprise only 8% of the total vehicle population. In India currently only transport vehicles, that is, vehicles used for hire or reward are required to undergo periodic fitness certification. The large population of personalised vehicles are not yet covered by any such mandatory requirement.In most countries that have been able to control vehicular pollution to a substantial extent, Inspection & Maintenance of all categories of vehicles have been one of the chief tools used. Developing countries in the South East Asian region, which till a few years back had severe air pollution problem have introduced an I&M system and also effective traffic management. ROAD & TRAFFIC MANAGEMENT Inadequate and poor quality of road surface leads to increased Vehicle Operation Costs and also increased pollution. It has been estimated that improvements in roads will result in savings of about 15% of Vehicle Operation Costs.CONCLUSION The need for an integrated, holistic approach for controlling vehicular emission cannot be over-emphasised. More importantly, it is time now for the auto and oil industry to come together under the guidance of the Government in evolving fuel quality standards and vehicular technology to meet air quality targets. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* For Catalytic Converter Fitted vehicles upto 6 seaters(A)& GVW upto 2.5 tons More than 6 seaters(B)& GVW upto 3.5 tons(A)(B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

↧

History of Emission Norms in India

↧

Scientists Debate Whether Carbon Capture Could Cause Earthquakes

IMT Staff posted on November 15, 2013 http://www.engineering.com

Carbon capture and storage (CCS) is designed to help coal plants and other installations reduce the amount of CO2 in the atmosphere by isolating the CO2 before it goes up the smokestack, pressurizing it, then injecting it into the ground. It’s an unproven technology on a large scale, expensive, and as some analysts say, necessary to help coal-fired power plants comply with the Environmental Protection Agency’s (EPA) stringent rules on carbon emissions.

Carbon capture and storage (CCS) is designed to help coal plants and other installations reduce the amount of CO2 in the atmosphere by isolating the CO2 before it goes up the smokestack, pressurizing it, then injecting it into the ground. It’s an unproven technology on a large scale, expensive, and as some analysts say, necessary to help coal-fired power plants comply with the Environmental Protection Agency’s (EPA) stringent rules on carbon emissions.Further fueling the debate on CCS is research that shows the process CCS could cause earthquakes.

‘High Probability’ of Earthquakes from ‘Large’ CO2 Injections.In a 2012 study, Stanford University’s Mark D. Zoback and Steven M. Gorelick assert that “there is a high probability that earthquakes will be triggered by injection of large volumes of CO2 into the brittle rocks commonly found in continental interiors. Because even small- to moderate-sized earthquakes threaten the seal integrity of CO2 repositories, in this context, large-scale CCS is a risky, and likely unsuccessful, strategy for significantly reducing greenhouse gas emissions.”

The assertion by the Stanford researchers prompted the Washington-based newspaper the Kitsap Sun to draw a parallel to research at a West Texas oil field that “experienced 93 earthquakes in 2009 and 2010, some of which were Magnitude 3 or greater.”

Seismologists Wei Gan of China University of Geosciences and Cliff Frohlich of the University of Texas-Austin found that from 2006 to 2011 earthquakes occurred near the Cogdell oil field near Snyder, Texas.

“A previous series of earthquakes occurring 1975 to 1982 was attributed to the injection of water into wells to enhance oil production,” they wrote in the Proceedings of the National Academy of Sciences journal. “Water injection cannot explain the 2006–2011 earthquakes.”

Not The Water, the CO2.

Gan and Frohlich noted that since 2004 significant amounts of gas, including carbon dioxide, had been injected into the Cogdell wells.

“If this triggered the 2006-2011 seismicity, this represents an instance where gas injection has triggered earthquakes having magnitudes of 3 ane larger,” they wrote. “Understanding when gas injection triggers earthquakes will help evaluate the risks associated with large-scale carbon capture and storage as a strategy for managing climate change.”

The Cogdell oil field was flooded from 1957 and 1982 to boost the petroleum production and “a contemporary analysis concluded this induced earthquakes that occurred between 1975 and 1982,” Gan and Frolich wrote. The National Earthquake Information Center detected no further activity between 1983 and 2005.

Seismograph stations deployed by the USArray program identified 93 earthquakes occurring between March 2009 and December 2010 in the vicinity of the Cogdell field.

↧

↧

Oil and Gas Industries Lead the Way in CO2 Reduction

David Sims posted on October 04, 2013 |

U.S. carbon dioxide emissions are at their lowest levels in 20 years — thanks to the oil and gas industry.

U.S. carbon dioxide emissions are at their lowest levels in 20 years — thanks to the oil and gas industry.“Oil and natural gas companies are America’s top investors in zero- and low-greenhouse gas emissions (GHG) technologies,” according to a new study released by API (American Petroleum Institute).

“America’s oil and natural gas companies have invested more to reduce greenhouse gas emissions than the federal government and almost as much as all other industries combined,” API Vice President for Policy and Economic Analysis Kyle Isakower said recently in The Maritime Executive.

Oil And Gas: Half Of All Investment.The study was conducted by T2 and Associates, and looked at investment in GHG mitigation technology from 2000 through 2012. “During that period, the U.S. oil and natural gas industry directly invested approximately $81 billion in GHG mitigation technologies,” The Maritime Executive reported. “Other U.S. industries invested an estimated $91.2 billion, and the federal government invested an estimated $79.7 billion.”

If you include shale investments, the amount credited to the oil and natural gas industry expenditures on GHG mitigation balloons to $165.4 billion, which is half of the total invested by all industries and the federal government over that time.

Emissions of CO2 in the U.S. have been slowing for years. The Energy Information Administration (EIA) reported last August that “energy-related greenhouse gas emissions in the United States declined in 2011 by 2.9 percent compared to 2010 and an additional 2.1 percent in 2012 compared to 2010.” Last year, emissions were 705 million metric tons below the 2005 level, or 13 percent less, and in fact, “energy-related carbon dioxide emissions have declined in the United States in four out of the last six years.”

And the API suggests that the greenhouse gas reductions achieved by the oil and gas industry are probably understated. “The emission reduction estimates for 2008-2012 presented herein were compiled strictly from company reports,” the institute notes, adding that “there are indications that this summary of reported reductions is an underestimate of actual reductions.”

In other words, the news is almost certainly better than reported because “not all companies reported emission reductions, so the reductions compiled here are likely conservative,” the API said. Reductions in methane emissions reported in EPA’s Natural Gas STAR program “are substantially greater than the total reported here,” and “emissions reductions from substituting natural gas for coal are not included in reported emission reductions by oil and gas companies, but are significant in reducing overall emissions.”

In other words, what was counted is impressive, but there are certainly other reductions that have not been tallied. It’s interesting to note some of the reasons given for declines — and upticks — in CO2 emissions. For instance, America’s GDP grew by 3.0 percent last year, while “emissions increased by 3.9 percent,” which the API attributed to increased use of coal-fired power to do the things that gradually improving economies do. There was a decrease in the nation’s GHG emissions in 2011, “primarily from mild weather and a declining price of natural gas that caused fuel switching away from coal to natural gas in the electric power sector,” as well as federal EPA regulations forcing many to switch from coal to gas to generate electricity.

Reduced Emissions? A Happy Byproduct.The interesting thing is that reduced emissions aren’t always the result of investments targeted specifically for that purpose. Most of the investments made by the approximately 650 companies involved in the API study “provide benefits in addition to any ability to reduce greenhouse gas emissions, and were made for multiple reasons including to increase or diversify energy supplies, or to improve efficiency.”Case in point: Of all the investments made by the oil and gas industry which reduced emissions, by far the largest one, $109 billion worth, accounting for 66 percent of the total invested, was in fuel substitution — specifically, expanding shale gas development. Shale gas emits less CO2 than other fuels, but it’s also a lot cheaper.

↧

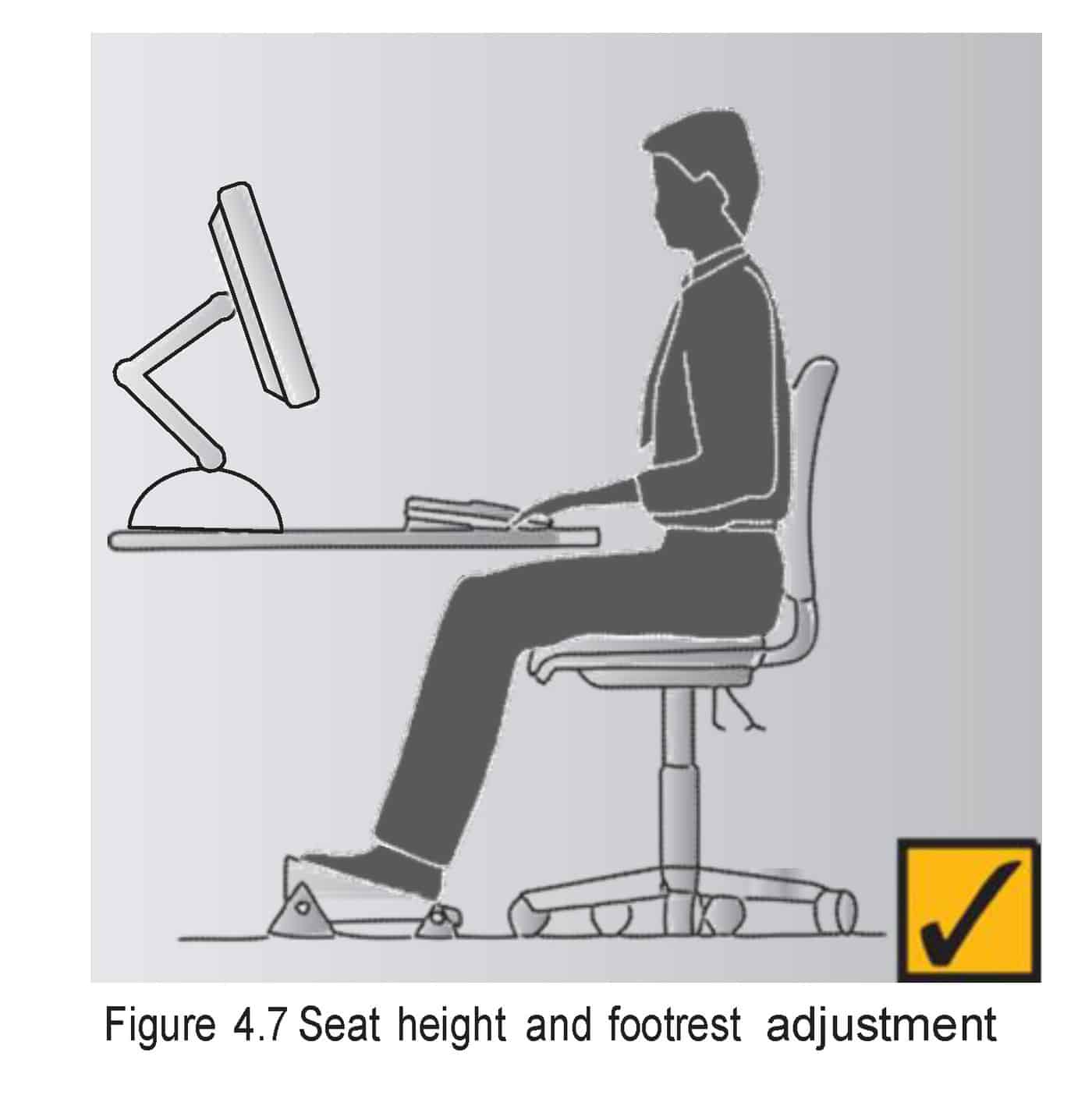

Lovely chair that helps greatly but is only part of the solution

Lovely chair that helps greatly but is only part of the solution

A diagram of safe posture at modern workstations has become iconic but it has also become a symbol of ergonomic misunderstanding. There are assumptions behind the angular figure about the way modern workers work, the equipment used and the tasks undertaken.

A diagram of safe posture at modern workstations has become iconic but it has also become a symbol of ergonomic misunderstanding. There are assumptions behind the angular figure about the way modern workers work, the equipment used and the tasks undertaken.Too often images, such as the one included here, are taken out of context. The image is used as a shortcut to what is considered the “correct” way to sit. The context, the risk assessments, the tasks undertaken, the location of the workstation – basically all of the OHS information included in the workplace safety guides is ignored. People think “the picture has a tick of approval, so why read when the picture says enough”?

This week Steelcase, a one hundred year old company that originally constructed waste paper baskets, launched its Gesture chair. The marketing of this chair is based on the discovery (?) of nine new postures in the workplace:

↧

CAS Technical Conference (TECO) on "Responding to the Environmental Stressors of the 21st Century"

The World Meteorological Organization (WMO) is organizing the Technical Conference on "Responding to the Environmental Stressors of the 21st Century" (Antalya, Turkey, 18 and 19 November 2013). The Conference will be held in connection with the Sixteenth Session of the Commission for Atmospheric Sciences (CAS-16) which is scheduled from 20 to 26 November 2013. At the kind invitation of the Government of Turkey, both events will be hosted by the Turkish State Meteorological Service (TSMS).

Topics

• High Impact Weather and its socio-economic effects in the context of global change

• Water: Modelling and predicting the water cycle for improved DRR and resource

management

• Integrated GHG Information System: Serving society and supporting policy

• Aerosols: Impacts on air quality, weather and climate

• Urbanization: Research and services for megacities and large urban complexes.

• Evolving technologies: Their impact on science and its use (satellite technology and other

remote sensing, computing power, social media etc.) including geoengineering.

The Conference will consist of key-note talks, oral presentations and a poster session. It will be co-chaired by Dr Gilbert Brunet of the UK MetOffice and Prof. Øystein Hov of the Norwegian Meteorological Institute.

• High Impact Weather and its socio-economic effects in the context of global change

• Water: Modelling and predicting the water cycle for improved DRR and resource

management

• Integrated GHG Information System: Serving society and supporting policy

• Aerosols: Impacts on air quality, weather and climate

• Urbanization: Research and services for megacities and large urban complexes.

• Evolving technologies: Their impact on science and its use (satellite technology and other

remote sensing, computing power, social media etc.) including geoengineering.

The Conference will consist of key-note talks, oral presentations and a poster session. It will be co-chaired by Dr Gilbert Brunet of the UK MetOffice and Prof. Øystein Hov of the Norwegian Meteorological Institute.

Background

In an era of rapid global change, humanity is experiencing new and evolving threats to sustainability. Many of these threats are related to a complex combination of weather, climate, water, and related environmental phenomena with a growing and urbanizing population. The 21st Century will be a challenging time in which many established practices will require modification to accommodate the limitations imposed by the Earth which has finite dimensions and resources. Policies and decisions that minimize risk and maximize benefits from favourable environmental conditions will require sound, relevant and well communicated scientific information on the atmosphere, its processes and the potential impacts these could have on humans and the environment. This information will range from enhanced long-term measurements and understanding of the background atmospheric composition to user-friendly weather and related environmental predictions ranging from the next few minutes to months ahead.

Objectives

•To give an opportunity to review some of the primary scientific and research challenges

related to CAS that WMO Members are facing;

• To highlight and discuss some of the focus areas of relevance to the Global Atmosphere

Watch (GAW) Programme and its GAW Urban Research Meteorology and Environment

(GURME) project;

• To consider emerging research issues related to the World Weather Research Programme

(WWRP) including the post THORPEX legacy projects, and the cross-cutting activities with

the World Climate Research Programme (WCRP);

• To obtain feedbacks from CAS members that can be considered in aligning CAS activities

and ensuring their value for WMO Members;

• To discuss methods to ensure the support and participation of WMO Members in the

activities of CAS.

In an era of rapid global change, humanity is experiencing new and evolving threats to sustainability. Many of these threats are related to a complex combination of weather, climate, water, and related environmental phenomena with a growing and urbanizing population. The 21st Century will be a challenging time in which many established practices will require modification to accommodate the limitations imposed by the Earth which has finite dimensions and resources. Policies and decisions that minimize risk and maximize benefits from favourable environmental conditions will require sound, relevant and well communicated scientific information on the atmosphere, its processes and the potential impacts these could have on humans and the environment. This information will range from enhanced long-term measurements and understanding of the background atmospheric composition to user-friendly weather and related environmental predictions ranging from the next few minutes to months ahead.

Objectives

•To give an opportunity to review some of the primary scientific and research challenges

related to CAS that WMO Members are facing;

• To highlight and discuss some of the focus areas of relevance to the Global Atmosphere

Watch (GAW) Programme and its GAW Urban Research Meteorology and Environment

(GURME) project;

• To consider emerging research issues related to the World Weather Research Programme

(WWRP) including the post THORPEX legacy projects, and the cross-cutting activities with

the World Climate Research Programme (WCRP);

• To obtain feedbacks from CAS members that can be considered in aligning CAS activities

and ensuring their value for WMO Members;

• To discuss methods to ensure the support and participation of WMO Members in the

activities of CAS.

↧

↧

Carbon monooxide poisoning -You can’t see it, taste it or smell it but it can kill quickly and with no warning.

Carbon monoxide poisoning – What are the symptoms?

You can’t see it, taste it or smell it but it can kill quickly and with no warning.

Unsafe gas appliances produce a highly poisonous gas called carbon monoxide (CO). It can cause death as well as serious long term health problems such as brain damage.

Remember the six main symptoms to look out for:

- headaches

- dizziness

- nausea

- breathlessness

- collapse

- loss of consciousness

Being aware of the symptoms could save your life.

Carbon monoxide symptoms are similar to flu, food poisoning, viral infections and simply tiredness. That’s why it’s quite common for people to mistake this very dangerous poisoning for something else.Other signs that could point to carbon monoxide poisoning:

- Your symptoms only occur when you are at home

- Your symptoms disappear or get better when you leave home and come back when you return

- Others in your household are experiencing symptoms (including your pets) and they appear at a similar time

What should I do if I experience any symptoms of carbon monoxide poisoning?

- Get fresh air immediately. Open doors and windows, turn off gas appliances and leave the house

- See your doctor immediately or go to hospital - let them know that you suspect carbon monoxide poisoning. They can do a blood or breath test to check

- If you think there is immediate danger, Emergency Helpline

- Get a Gas Safe registered engineer to inspect your gas appliances and flues to see if there is a dangerous problem

What is carbon monoxide?

Carbon monoxide (CO) is a highly poisonous substance produced by the incomplete burning of gas and Liquid Petroleum Gas (LPG).This happens when a gas appliance has been incorrectly fitted, badly repaired or poorly maintained. It can also occur if flues, chimneys or vents are blocked.

Oil and solid fuels such as coal, wood, petrol and oil can also produce carbon monoxide.

What is carbon monoxide poisoning?

Carbon monoxide poisoning occurs when you breathe in even small amounts of the gas.When you breathe in carbon monoxide, it gets into your blood stream and prevents your red blood cells from carrying oxygen. Without oxygen, your body tissue and cells die.

Levels that do not kill can cause serious harm to health when breathed in over a long period of time. Long term effects of carbon monoxide poisoning include Paralysis and brain damage. Such long term effects occur because many people are unaware of unsafe gas appliances and subsequent gas leaks.

How do I avoid a carbon monoxide leak in my home?

Your home may show signs of carbon monoxide. Any one of the following could be a sign that there is carbon monoxide in your home.- The flame on your cooker should be crisp and blue. Lazy yellow or orange flames mean you need to get your cooker checked

- Dark staining around or on appliances

- Pilot lights that frequently blow out

- Increased condensation inside windows

Why should I get a carbon monoxide alarm?

Because carbon monoxide has no taste, smell or colour. Gas Safe Register strongly recommends you fit an audible carbon monoxide alarm in your home.While an alarm will alert you to carbon monoxide in your home, it is no substitute for having an annual gas safety check and regular servicing by a Gas Safe registered engineer.

A carbon monoxide alarm looks similar to a smoke alarm and is very easy to fit by following the manufacturer’s instructions. You can purchase a carbon monoxide alarm from £15 at your local DIY store, supermarket or from your energy supplier.

Before purchasing a carbon monoxide alarm, always make sure it is marked to EN 50291. It should also have the British Standards' Kitemark or another European approval organisation's mark on it. Follow the alarm manufacturer’s instructions on siting, testing and replacing the alarm.

You are particularly at risk from carbon monoxide poisoning while sleeping, as you may not be aware of early carbon monoxide symptoms until it’s too late. Do not use the ‘black spot’ detectors that change colour when carbon monoxide is present. These will not make a sound to wake you up if the poisonous gas is present while you are sleeping.

↧

Adult Male Chemical Burn to Body

Adult Male Chemical Burn to Body

↧

WISHING A VERY HAPPY BIRTH DAY TO LATE SHRI KVK Raju SIR (born November 28, 1928)

OUR BELOVED FOUNDER LATE SHRI KVK RAJU SIR SERVING SOCIETY THROUGH INDUSTRY , MAINTAINING HARMONY WITH NATURE

KVK Raju (born November 28, 1928), whose surname is Kanumuri, was a first generation technopreneur born in a humble agricultural family in Andhra Pradesh. He was the founder of the Nagarjuna Group of companies. He was born in a small village at Ai Bhimavaram in West Godavari District, Andhra Pradesh. He belonged to a family which has played a part in the struggle for political freedom in India

He was born to Shri Kanumuri Venkata Narasimha Raju a Landlord and Shrimati Subbamma, a pious lady. KVK Raju had his elementary education in a local school during 1933-38. he passed Secondary School Leaving Certificate Course from Sri Rama Krishna Mission School, Tanuku in 1945. He was the first batch of Intermediate in 1945-46 at West Godavari Bhimavaram (WGB) College, subsequently renamed D.N.R College.

![]()

He was born to Shri Kanumuri Venkata Narasimha Raju a Landlord and Shrimati Subbamma, a pious lady. KVK Raju had his elementary education in a local school during 1933-38. he passed Secondary School Leaving Certificate Course from Sri Rama Krishna Mission School, Tanuku in 1945. He was the first batch of Intermediate in 1945-46 at West Godavari Bhimavaram (WGB) College, subsequently renamed D.N.R College.

During 1947-49, KVK Raju studied B.Sc course in Banaras Hindu University at Varanasi and later he joined the Madras Institute of Technology at Choromepet, Madras and did Automobile Engineering. He went on to complete his Master's in Mechanical and Industrial Engineering from Michigan State University and the University of Minnesota, USA.

http://dramarnathgiri.blogspot.in/2012/10/the-nagarjuna-group-under-stewardship.html

http://dramarnathgiri.blogspot.in/?view=magazine

https://www.google.co.in/#q=http:%2F%2Fdramarnathgiri.blogspot.in%2F]

https://www.google.co.in/search?q=http://dramarnathgiri.blogspot.in/&source=lnms&tbm=isch&sa=X&ei=0bmNUvyYCcGPrQfIi4GQBw&ved=0CAcQ_AUoAQ&biw=999&bih=576

http://dramarnathgiri.blogspot.in/2012/10/the-nagarjuna-group-under-stewardship.html

http://dramarnathgiri.blogspot.in/?view=magazine

https://www.google.co.in/#q=http:%2F%2Fdramarnathgiri.blogspot.in%2F]

https://www.google.co.in/search?q=http://dramarnathgiri.blogspot.in/&source=lnms&tbm=isch&sa=X&ei=0bmNUvyYCcGPrQfIi4GQBw&ved=0CAcQ_AUoAQ&biw=999&bih=576

↧

Cyclone Helen to cross Andhra coast tomorrow afternoon

↧

↧

Weather History for Kakinada, India Friday, November 22, 2013

| Actual | Average | Record | |

|---|---|---|---|

| Temperature | |||

| Mean Temperature | 23 °C | - | |

| Max Temperature | 25 °C | - | - () |

| Min Temperature | 21 °C | - | - () |

| Cooling Degree Days | 9 | ||

| Growing Degree Days | 24 (Base 50) | ||

| Moisture | |||

| Dew Point | 24 °C | ||

| Average Humidity | 95 | ||

| Maximum Humidity | 97 | ||

| Minimum Humidity | 91 | ||

| Precipitation | |||

| Precipitation | 20 mm | - | - 20 |

| Sea Level Pressure | |||

| Sea Level Pressure | 1007.40 hPa | ||

| Wind | |||

| Wind Speed | 16 km/h () | ||

| Max Wind Speed | 28 km/h | ||

| Max Gust Speed | - | ||

| Visibility | 7.6 kilometers | ||

| Events | Rain | ||

| T = Trace of Precipitation, MM = Missing Value | Source: Averaged Metar Reports |

| Nov. 22, 2013 | Rise | Set |

|---|---|---|

| Actual Time | 6:09 AM IST | 5:25 PM IST |

| Civil Twilight | 5:46 AM IST | 5:48 PM IST |

| Nautical Twilight | 5:19 AM IST | 6:14 PM IST |

| Astronomical Twilight | 4:53 AM IST | 6:40 PM IST |

| Moon | 9:22 PM IST | 9:41 AM IST |

| Length Of Visible Light | 12h 02m | |

| Length of Day | 11h 16m | |

| Waning Gibbous, 81% of the Moon is Illuminated | ||||

Today Waning Gibbous | Nov 26 Last Quarter | Dec 3 New | Dec 9 First Quarter | Dec 17 Full |

Hourly Weather History & Observations

| Time (IST) | Temp. | Dew Point | Humidity | Pressure | Visibility | Wind Dir | Wind Speed | Gust Speed | Precip | Events | Conditions |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2:30 AM | 24 °C | 22 °C | 91% | 1005 hPa | 4 km | NE | 27.8 km/h / | - | - | Rain | Light Rain |

| 5:30 AM | 25 °C | 24 °C | 93% | 1005 hPa | 4 km | ENE | 22.2 km/h / | - | - | Partly Cloudy | |

| 8:30 AM | 25 °C | 24 °C | 95% | 1009 hPa | 10 km | East | 18.5 km/h / | - | - | Rain | Rain |

| 11:30 AM | 25 °C | 25 °C | 97% | 1010 hPa | 10 km | ENE | 14.8 km/h / | - | - | Rain | Rain |

| 2:30 PM | 25 °C | 25 °C | 97% | 1008 hPa | 10 km | ESE | 11.1 km/h / | - | - | Rain | Rain |

↧

CYCLONE RELATED PDF FOLDER RELEASED BY IMD

Ancient Beginnings :

The beginnings of meteorology in India can be traced to ancient times. Early philosophical writings of the 3000 B.C. era, such as the Upanishadas, contain serious discussion about the processes of cloud formation and rain and the seasonal cycles caused by the movement of earth round the sun. Varahamihira's classical work, the Brihatsamhita, written around 500 A.D., provides a clear evidence that a deep knowledge of atmospheric processes existed even in those times. It was understood that rains come from the sun (Adityat Jayate Vrishti) and that good rainfall in the rainy season was the key to bountiful agriculture and food for the people. Kautilya's Arthashastra contains records of scientific measurements of rainfall and its application to the country's revenue and relief work. Kalidasa in his epic, 'Meghdoot', written around the seventh century, even mentions the date of onset of the monsoon over central India and traces the path of the monsoon clouds.

Depression over Bay of Bengal (29-31 May)

Depression over Bay of Bengal (30th July-1st August)

Very Severe Cyclonic Strom "PHAILIN" (08th-14th October2013)

Very Severe Cyclonic Strom "PHAILIN" (08th-14th October2013) ↧

WORK AREA SAFETY CHECKLIST

| mpany: | Work Area: |

| Inspected by: | Date of Inspection: |

WORK AREA SAFETY CHECKLIST

| General Work Environment | Yes | No |

| Worksites clean and orderly? | ___ | __ |

| Work surfaces kept dry or appropriate means taken to assure the surfaces are slip-resistant? | ___ | __ |

| All spilled materials or liquids cleaned up immediately? | ___ | __ |

| Combustible scrap, debris and waste stored safely and removed from the worksite promptly? | ___ | __ |

| Accumulations of combustible dust routinely removed from elevated surfaces including the overhead structure of the buildings? | ___ | __ |

| Combustible dust cleaned up with a vacuum system to prevent the dust going into suspension? | ___ | __ |

| Metallic or conductive dust prevented from entering or accumulating on or around electrical enclosures or equipment? | ___ | __ |

| Covered metal waste cans used for oily and paint soaked waste? | ___ | __ |

| Oil and gas fired devices equipped with flame failure controls that will prevent flow of fuel if pilots or main burners are not working? | ___ | __ |

| At least minimum number of toilets and washing facilities provided? | ___ | __ |

| Toilets and washing facilities clean and sanitary? | ___ | __ |

| Work areas adequately illuminated? | ___ | __ |

| Pits and floor openings covered or otherwise guarded? | ___ | __ |

| Exiting or Egress | Yes | No |

| All exits marked with an exit sign and illuminated by a reliable light source? | ___ | __ |

| Are the directions to exits, when not immediately apparent, marked with visible signs? | ___ | __ |

| Doors, passageways or stairways, that are neither exits nor access to exits and which could be mistaken for exits, appropriately marked "NOT AN EXIT", etc. | ___ | __ |

| Exit signs provided with the word "EXIT" in lettering at least 5 inches high and the stroke of the lettering at least 1/2 inch wide? | ___ | __ |

| Exit doors side-hinged? | ___ | __ |

| All exits kept free of obstructions? | ___ | __ |

| At least two means of egress provided from elevated platforms, pits or rooms where the absence of a second exit would increase the risk of injury? | ___ | __ |

| Sufficient exits to permit prompt escape in case of an emergency? | ___ | __ |

| Special precautions taken to protect employees during construction and repair operations? | ___ | __ |

| Is the number of exits from each floor of a building and the number of exits from the building itself appropriate for the building occupancy load? | ___ | __ |

| Exits stairways that are required to be separated from other parts of a building enclosed by at least two-hour, fire-resistive construction in buildings more than four stories high, and not less than one-hour fire resistive construction elsewhere? | ___ | __ |

| When ramps are used as part of required exiting from a building, is the ramp slope limited to 1 foot vertical to 12 feet horizontal? | ___ | __ |

| When an exit must be made through an unframed glass door, glass exit door, etc. are the doors fully tempered and do they meet the safety requirements for human impact? | ___ | __ |

| Exit Doors | Yes | No |

| Doors that are required to serve as exits designed and constructed so that the way of exit travel is obvious and direct? | ___ | __ |

| Windows that could be mistaken for exit doors made inaccessible by means of barriers or railing? | ___ | __ |

| Exit doors able to open from the direction of exit travel without the use of a key or any special knowledge or effort when the building is occupied? | ___ | __ |

| Are revolving, sliding, or overhead doors prohibited from serving as a require exit door? | ___ | __ |

| Where hardware installed on a required exit door allow the door to open by applying a force of 15 pounds or less in the direction of the exit traffic? | ___ | __ |

| Doors on cold storage rooms provided with an inside release mechanism that will release the latch and open the door even if it's padlocked or otherwise locked on the outside? | ___ | __ |

| When exits doors open directly onto any street, alley, or other area where vehicles may be operated, are barriers and warning provided to prevent employees from stepping into the path of traffic? | ___ | __ |

| Are there viewing panels in doors that swing in both directions and are located between rooms where there is frequent traffic? | ___ | __ |

| Portable Ladders | Yes | No |

| Ladders maintained in good condition, joints between steps and side rails tight, all hardware and fittings securely attached and movable parts operating freely without binding or undue play? | ___ | __ |

| Non slip safety feet provided on each metal or rung ladder? | ___ | __ |

| Ladder rungs and steps free of grease and oil? | ___ | __ |

| Is it prohibited to place a ladder in front of door openings towards the ladder except when the door is blocked open, locked or other wise guarded? | ___ | __ |

| Is it prohibited to place ladders on boxes, barrels or other unstable bases to obtain additional height? | ___ | __ |

| Are employees instructed to face the ladder when ascending or descending? | ___ | __ |

| Employees prohibited from using ladders that are broken, missing steps, rungs, or cleats, have broken side rails, or from using other faulty equipment? | ___ | __ |

| Employees instructed not to use the top step of ordinary stepladders as a step? | ___ | __ |

| When portable rung ladders are used to gain access to elevated platforms, roof, etc., does the ladder always extend at least 3 feet above the elevated surface? | ___ | __ |

| When portable rung or cleat ladders are used, is it required the base places so that slipping will not occur or it is lashed or other wise held in place? | ___ | __ |

| Portable metal ladders legibly marked with signs reading "CAUTION: Do not use around electrical equipment" or equivalent wording? | ___ | __ |

| Employees prohibited from using ladders as guys, braces, skids, gin poles, or for other than their intended purposes? | ___ | __ |

| Employees instructed to adjust extension ladders only while standing at the base, not while standing on the ladder or any position above the ladder? | ___ | __ |

| Walkways | Yes | No |

| Aisles and passageways kept clear? | ___ | __ |

| Aisles and walkways marked as appropriate? | ___ | __ |

| Wet surfaces covered with non-slip materials? | ___ | __ |

| Holes in the floor, sidewalk or other walking surfaces repaired properly, covered or other wise made safe? | ___ | __ |

| Are there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating? | ___ | __ |

| Materials or equipment stored in such a way that sharp projectiles will not interfere with the walkway? | ___ | __ |

| Spilled materials cleaned up immediately? | ___ | __ |

| Changes of direction or elevations readily identifiable? | ___ | __ |

| Aisles or walkways that pass near moving or operating machinery, welding operations or similar operations arranged so employees will not be subjected to potential hazards? | ___ | __ |

| Adequate headroom provided for the entire length of any aisle or walkway? | ___ | __ |

| Standard guardrails provided wherever aisle or walkway surfaces are elevated more than 30 inches above any adjacent floor or the ground? | ___ | __ |

| Bridges provided over conveyers and similar hazards equipped with proper railing? | ___ | __ |

| Floor and Wall Openings | Yes | No |

| Floor openings guarded by a cover, guardrail or equivalent on all sides (except entrance to stairways or ladders)? | ___ | __ |

| Toe boards installed around the edges of permanent floor openings? | ___ | __ |

| Skylight screens of such construction and mounting that they will with stand a load of at least 200 lbs. | ___ | __ |

| Glass in windows, doors, glass walls, etc. which are subject to human impact of sufficient thickness and type for the condition of use? | ___ | __ |

| Grates or similar type covers over floor openings, such as floor drains, of such design that foot traffic or rolling equipment will not be affected by the grate spacing? | ___ | __ |

| Unused portions of service pits and pits not actually in use either covered or protected by guardrails or equivalent? | ___ | __ |

| Manhole covers, trench covers and similar covers, plus their supports, designed to carry a truck rear axle load of at least 20,000 pounds when located in roadways and subject to vehicle traffic. | ___ | __ |

| Floor or wall openings in fire resistive construction provided with doors or covers compatible with the fire rating of the structure and provided with a self closing feature when appropriate? | ___ | __ |

| Stairs and Stairways | Yes | No |

| Standard stair rails or handrails on all stairways having four or more risers? | ___ | __ |

| Stairways at least 22 inches wide? | ___ | __ |

| Stairs have at least 6'6" clearance? | ___ | __ |

| Stairs angle no more than 50 and no less than 30 degrees? | ___ | __ |

| Stairs of hollow pan type treads and landing filled with solid material? | ___ | __ |

| Steps on stairs and stairways designed or provided with a surface that renders them slip resistant? | ___ | __ |

| Stairway handrails located between 30 and 34 inches above the leading edge of stair treads? | ___ | __ |

| Stairway handrails have at least 1 and 1/2 inches of clearance between the handrails and the wall or surface they are mounted on? | ___ | __ |

| Stairway handrails capable of withstanding a load of 200 pounds, applied in any direction? | ___ | __ |

| Where stairs or stairways exit directly into any area where vehicles may be operated, are adequate barriers and warnings provided to prevent employees from steeping into the path of traffic? | ___ | __ |

| Stairway landings have a dimension measured in the direction of travel, at least equal to the width of the stairway? | ___ | __ |

| Vertical distance between stairway landings limited to 12 feet or less? | ___ | __ |

| Stairway provided to the roof or each building 4 or more stories in height, provided the roof slope has a 4 inch drop in 12 inches or less? | ___ | __ |

| Elevated Surfaces | Yes | No |

| Signs posted, when appropriate, showing the elevated surface load capacity? | ___ | __ |

| Surfaces elevated more than 30 inches above the floor or ground provided with standard guardrails? | ___ | __ |

| Elevated surfaces (beneath which people or machinery could be exposed to falling objects) provided with standard four inch toe boards? | ___ | __ |

| Permanent means of access and egress provided to elevated storage and work surfaces? | ___ | __ |

| Required headroom provided where necessary? | ___ | __ |

| Material on elevated surfaces piled, stacked or racked in a manner to prevent it from tipping, falling, collapsing, rolling or spreading? | ___ | __ |

| Dock boards or bridge plates used when transferring materials between docks and trucks or rail cars? | ___ | __ |

↧

Stationary Scaffold Checklist

| roject Name: | Project Location: |

| Completed by: | Date: |

STATIONARY SCAFFOLD INSPECTION CHECKLIST

YES | NO | ACTION/COMMENTS | |

| Scaffold components and planking in safe condition for use and planks graded for scaffold use? | |||

| Frame spacing and sill size capable of carrying intended loading? | |||

| Competent person in charge of erection and to inspection? | |||

| Sills properly placed and adequate sized? | |||

| Screw jacks been used to level and plumb scaffold instead of unstable objects? | |||

| Base plates and/or screw jacks in firm contact with sills and frame? | |||

| Scaffold is level and plumb? | |||

| Scaffold legs braced with braces properly attached? | |||

| Guard railing in place on all open sides and ends? | |||

| Overhead protection or wire screening been provided where necessary? | |||

| Scaffold been tied to structure at least every 30' in length and 26' in height? | |||

| Free standing towers been guyed or tied every 26' in height? | |||

| Brackets, tube and clamp, and accessories been properly placed with nuts and bolts tightened? | |||

| Scaffold free of makeshift devices or ladders to increase height? | |||

| Planks have minimum 12" overlap and extend 6" beyond supports? | |||

| Toe boards properly installed? | |||

| Conditions such as power lines, wind loading, etc. controlled? | |||

| Safe way to get on and off the scaffold without climbing on cross braces? | |||

| Front face within 14 inches of the work or within three feet for outrigger scaffolds? |

↧

↧

Natural Gas-AVAILABILITY & UTILISATION OF NATURAL GAS

Natural Gas

AVAILABILITY & UTILISATION OF NATURAL GAS

- Natural gas has emerged as the most preferred fuel due to its inherent environmentally benign nature, greater efficiency and cost effectiveness. The demand of natural gas has sharply increased in the last two decades at the global level. In India too, the natural gas sector has gained importance, particularly over the last decade, and is being termed as the Fuel of the 21st Century.

- Production of natural gas, which was almost negligible at the time of independence, is at present at the level of around 87 million standard cubic meters per day (MMSCMD). The main producers of natural gas are Oil & Natural Gas Corporation Ltd. (ONGC), Oil India Limited (OIL) and JVs of Tapti, Panna-Mukta and Ravva. Under the Production Sharing Contracts, private parties from some of the fields are also producing gas. Government have also offered blocks under New Exploration Licensing Policy (NELP) to private and public sector companies with the right to market gas at market determined prices.

- Out of the total production of around 87 MMSCMD, after internal consumption, extraction of LPG and unavoidable flaring, around 74 MMSCMD is available for sale to various consumers.

- Most of the production of gas comes from the Western offshore area. The on-shore fields in Assam, Andhra Pradesh and Gujarat States are other major producers of gas. Smaller quantities of gas are also produced in Tripura, Tamil Nadu and Rajasthan States. OIL is operating in Assam and Rajasthan States, whereas ONGC is operating in the Western offshore fields and in other states. The gas produced by ONGC and a part of gas produced by the JV consortiums is marketed by the GAIL (India) Ltd. The gas produced by OIL is marketed by OIL itself except in Rajasthan where GAIL is marketing its gas. Gas produced by Cairn Energy from Lakshmi fields and Gujarat State Petroleum Corporation Ltd. (GSPCL) from Hazira fields is being sold directly by them at market determined prices.

- Natural gas has been utilised in Assam and Gujarat since the sixties. There was a major increase in the production & utilisation of natural gas in the late seventies with the development of the Bombay High fields and again in the late eighties when the South Bassein field in the Western Offshore was brought to production.

- The gas produced in the western offshore fields is brought to Uran in Maharashtra and partly in Gujarat. The gas brought to Uran is utilised in and around Mumbai. The gas brought to Hazira is sour gas which has to be sweetened by removing the sulphur present in the gas. After sweetening, the gas is partly utilised at Hazira and the rest is fed into the Hazira-Bijaipur-Jagdhishpur(HBJ) pipeline which passes through Gujarat, MadhyaPradesh, Rajasthan, U.P., Delhi and Haryana. The gas produced in Gujarat, Assam, etc; is utilised within the respective states.

- Natural Gas is currently the source of half of the LPG produced in the country. LPG is now being extracted from gas at Duliajan in Assam, Bijaipur in M.P., Hazira and Vaghodia in Gujarat, Uran in Maharashtra, Pata in UP and Nagapattinam in Tamil Nadu. Two new plants have also been set up at Lakwa in Assam and at Ussar in Maharastra in 1998-99. One more plant is being set up at Gandhar in Gujarat. Natural gas containing C2/C3, which is a feedstock for the Petrochemical industry, is currently being used at Uran for Maharashtra Gas Cracker Complex at Nagothane. GAIL has also set up a 3 lakh TPA of Ethylene gas based petrochemical complex at Auraiya in 1998-99.

- As against the total allocation of around 118 MMSCMD, the gas supplies by GAIL is of the order of 63 MMSCMD spread over about 300 major consumers. Around 32% is supplied to the fertiliser sector, 41% to power, 4% to sponge iron and the balance 23% (including shrinkage) goes to other sectors.

- Around 8.5 MMSCMD of gas is being directly supplied by the JVs/private companies at market prices to various consumers. This gas is outside the purview of the Government allocations.

- In pursuance of Government decision in February 2005, Minister (P&NG) led a delegation to Pakistan during 4-8 June 2005. During the talks, the two Ministers reviewed the Iran-Pakistan-India gas pipeline proposal. They agreed that the project, which envisaged supply of gas to Pakistan and India through a transnational pipeline, would go a long way in meeting the energy security requirements of the two countries, and thus should be seen as a significant project for the benefit of the people of these countries. The Indian and Pakistani delegations agreed to exchange information in regard to the financial structuring, technical, commercial, legal and related issues to realize a safe and secure world class project. To this end, it was agreed that the momentum pertaining to the project should be accelerated by constituting a Joint Working Group at the Secretary level at the earliest, which will meet regularly and report the progress to the Ministers to facilitate definitive decisions by them.

UTILISATION OF NATURAL GAS

Natural Gas Allocation & Supply Scenario

All India Region-Wise & Sector-Wise Gas Supply By GAIL - (2003-04)

| (MMSCMD) |

| Region/Sector | Power | Fertilizer | S. Iron | Others | Total |

|---|---|---|---|---|---|

| HVJ & Ex-Hazira | 12.61 | 13.63 | 1.24 | 9.81 | 37.29 |

| Onshore Gujarat | 1.66 | 1.04 | 2.08 | 4.78 | |

| Uran | 3.57 | 3.53 | 1.33 | 1.41 | 9.85 |

| K.G. Basin | 4.96 | 1.91 | 0.38 | 7.25 | |

| Cauvery Basin | 1.07 | 0.25 | 1.32 | ||

| Assam | 0.41 | 0.04 | 0.29 | 0.74 | |

| Tripura | 1.37 | 0.01 | 1.38 | ||

| Grand Total | 25.65 | 20.15 | 2.58 | 14.23 | 62.61 |

IMPORT OF NATURAL GAS TO INDIA THROUGH TRANSNATIONAL GAS PIPELINES.

(a) Iran-Pakistan-India (IPI) Pipeline Project

(a) Iran-Pakistan-India (IPI) Pipeline Project

- 10.1 An Indian delegation also visited Iran from 11-14 June 2005 and discussed the issue of import of natural gas from Iran through on-land pipeline transiting via Pakistan. Both sides noted with satisfaction that as a result of regular discussions on technical issues pertaining to the project, a Heads of Agreement between NIGEC and the Indian companies concerned had been finalized. With a view to undertaking further studies and discussions in regard to relevant issues so that the project could take off by early next year, it was agreed to establish a special JWG on the Iran-Pakistan-India gas pipeline project.

- 10.2 A Pakistani delegation led by the Secretary, Ministry of Petroleum and Natural Resources, Govt. of Pakistan visited New Delhi on July 12-13, 2005 for the first meeting of India-Pakistan JWG. The second meeting of the JWG was held in Islamabad on 8-9 September, 2005. The first meeting of the Special JWG on Iran-Pakistan-India Pipeline Project was held in New Delhi on 3-4 August, 2005. The second meeting of the Special JWG on Iran-Pakistan-India Pipeline Project was held in Tehran on 24th October,2005. The Indian side was led by Secretary (P&NG). Indian side has already appointed financial consultants i.e., M/s Ernst & Young and is in the process of finalizing appointment of legal & technical consultants for the project. During the 2nd JWG meeting, the Pakistani side informed that they will also shortly be appointing their Financial Consultants.

(b) Myanmar-Bangladesh-India Gas Pipeline Project.

- 11.1 A trilateral meeting between the Petroleum Ministers of India, Myanmar and Bangladesh held on 12.1.2005. After the meeting a Joint Press Statement was issued by the three Ministers. The three sides agreed to transport of natural gas from Myanmar to India by pipeline transiting through Bangladesh. The route of the pipeline will be determined by mutual agreements of the three Governments. It was also decided to establish a Techno-Commercial Working Committee (TCWC) comprising duly designated representatives of the three Governments to prepare a draft MOU prescribing the framework of cooperation among the three Governments, including the Myanmar-Bangladesh-India gas pipeline project. The MOU would be signed at Dhaka at the earliest mutually convenient date.

- 11.2 In pursuance of the MoU, a Techno-Commercial Working Committee has been constituted by the three Governments. The First Meeting of the TCWC was held on 24-25 February, 2005. The TCWC has finalized draft MoU proposed to be signed by the three oil Ministers.

- 11.3 However, there are certain bilateral issues which have to be sorted out with Bangladesh. Simultaneously, India is also exploring the other option of import of natural gas from Myanmar. A high level delegation led by Minister, Energy, of Myanmar recently visited India during July 5-7, 2005. All aspects of Myanmar-Bangladesh-India gas pipeline were discussed. Minister (P&NG) visited Bangladesh during 5-6 September 2005 to pursue the matter with Government of Bangladesh. The matter is being pursued vigorously and the proposed gas imports from Myanmar would be finalized shortly notwithstanding the response of Government of Bangladesh. GAIL has been asked to do a pre-feasibility study of the onland pipeline route from Myanmar to India through North-Eastern Indian States, bypassing Bangladesh territory. The option of getting Bangladesh on board is also being simultaneously pursued. Another official level meeting was held in Yangon on 29-30 August 2005, where two sides agree to take definite steps for gas supply from Myanmar.

(c) Turkmenistan-Afghanistan-Pakistan (TAP) pipeline

Liquefied Natural Gas (LNG)

- Dedicated gas field development and production.

- Liquefaction plant.

- Transportation in special vessels.

- Regassification Plant.

- Transportation & distribution to the Gas consumer.

LNG Imports to India

LNG Projects

GAS PRICING

- ONGC and OIL produced about 55 MMSClMD APM gas from nominated fields. The determination of producer price for this gas will be referred to the Tariff Commission. Till the Commission submits its recommendation and a decision is taken thereon, the consumer price of APM gas will be increased from Rs.2850/MCM to a fixed price of Rs. 3200/MCM on adhoc basis.

- It has been decided that all available APM gas would be supplied to only the power and fertilizer sector consumers against their existing allocations along with the specific end users committed under Court orders/small scale consumers having allocations upto 0.05 MMSCMD at the revised price of Rs. 3200/MCM. This price is linked to a calorific value of 10,000 K.cal/cubic metre. However, the gas price for transport sector (CNG), Agra-Ferozabad small industries and other small scale consumers having allocations upto 0.05 MMSCMD would be progressively increased over the next 3 to 5 years to reflect the market price.

- The gas supplies through GAIL network to non-APM consumers will be at the price at which GAIL buys from JV producers at landfall point, subject to a ceiling of ex-Dahej RLNG price of US$3.86/MMBTU for the current year i.e. 2005-06. For the North-East region, Rs.3200/MCM will be considered as the market price during 2005-06.

- The price of gas for the North-Eastern region will be pegged at 60% of the revised price for general consumers. Thus, the consumer price for the North-East region will increase from the existing price of Rs.1700 to Rs.1920/MCM.

- Subject to the determination of producer price, based on the recommendations of the Tariff Commission, any additional gas as well as future production of gas from new fields to be developed in future by ONGC/OIL will be sold at market-related price in the context of NELP provisions.

REGULATORY FRAMEWORK FOR THE GAS INDUSTRY

↧

CONSERVATION OF PETROLEUM PRODUCTS

CONSERVATION OF PETROLEUM PRODUCTS

Oil and gas conservation means their better and more efficient use with regard to economic, social or environmental costs and benefits, resulting in attainment of higher energy use efficiencies, minimization of wasteful practices and wastage and protection of the environment.

2. Despite discovery of new sources of unconventional energy and due to existing inadequacies in supply of other forms of commercial energy relative to demand, petroleum remains the primary energy source in India and a preferred swing fuel. Its consumption has been increasing at a very steep rate from 3.5 MMT in 1950-51 to 84.3 MMT in 1997-98 and projected to reach 130 MMT in 2001-02 and 175 MMT in 2006-07.

3. Out of the known Indian reserves of 660 MMT of Crude Oil and 648 Billion Cubic Metres of Natural Gas, only a part may be technically and economically feasible to exploit. This fact, coupled with the present and expected consumption rates implies that these reserves may not last even 10 years. Our present indigenous production is only 33 MMT and is less than 50% of our annual requirement. Therefore, the Government attaches high priority to minimizing the gaps between indigenous production and consumption of petroleum products. The need of the hour is to conserve petroleum by its judicious use, substituting it by other resources wherever feasible and restricting its use only to the essential needs.

4. Various steps are being taken to promote conservation of petroleum products in the following areas. The following specific activities are taken up from time to time.

IN HOUSE CONSERVATION IN UPSTREAM AND REFINING SECTORS

Effective and result-oriented conservation methods adopted by the upstream undertakings in the oil sector include reduction of gas flaring by re-injection of gas to underground reservoir, installation of waste heat recovery systems, utilization of non-conventional energy sources and close monitoring of all conservation efforts by ONGC and OIL. Energy audits, efficiency upgradation of equipment and appliances; substitution of diesel with Natural Gas, deployment of solar-powered illumination panel, battery operated vehicles, Bio-gas etc., are other steps taken.

The oil refineries implement various schemes like revamp and replacement of low efficiency furnaces and boilers, installation of heat exchangers, economizers and co-generation equipment, and adoption of improved house keeping practices. They benchmark energy consumption levels with international pacesetters for improvement. They also implement ‘ENCON’ (Energy Conservation) schemes like heat integration and technology upgradation for yield-energy optimization, vapour recovery system to arrest the avoidable escape of gases through flare, tank seal etc.

In addition, they have implemented an Action Plan to produce and sell high grade lubricants to the extent of about 2.5 lakh tonnes per year to replace the lubricants of lower efficiency, in a phased manner and constantly upgrade lubricants in line with the international developments meeting Euro Standards. Multi-grade railroad engine oils with diesel saving potential have been developed for introduction in Indian Railways.

(D) Although transport losses are inevitable while moving the petroleum products by import tankers and coastal tankers over sea routes and at ports of unloading, a number of steps taken by the Ministry to keep the loss down to the lowest level have led to a progressive reduction.

As a part of the Government’s response to the oil crisis of early seventies, the PCRA was set up in 1976 to undertake studies to identify the potential and to make recommendations for achieving conservation of petroleum products in various sectors of the economy. It sponsors R&D activities for the development of fuel-efficient equipment / devices and organizes multi-media campaigns for creating mass awareness for the conservation of petroleum products. Fuel oil utilization studies, energy audits, boiler modernization scheme, introduction of equipment bank concept, use of energy vans, development of oil consumption norms, model depot projects, driver training programs, demonstration clinics/ workshops/ exhibitions, consumer meets, education films/TV spots, hoarding/ electronic display, distribution of printed literature, R&D projects are other activities.

6.1 MULTI MEDIA MASS AWARENESS PROGRAMME

Multi-media campaigns to create mass awareness about the need for conserving petroleum products and motivating users to take concrete steps to actually conserve are undertaken by PCRA and the Oil Marketing Companies through various media such as TV, Radio, Press, printed literature, outdoor publicity. Extensive use of Publicity Van of the Government Field Publicity Department of the States is made for increasing the reach amongst the consumers in the semi-urban and rural segments.

6.2 OIL CONSERVATION FORTNIGHT (OCF)

The success of the first Oil Conservation Week (OCW) organized in January, 1991 has led to its continuance in the subsequent years and finally, an extension to Oil Conservation Fortnights (OCF) from 1997. These are organized by the entire Oil Sector in close coordination with the concerned Ministries / Departments of the Union and State Governments, Public Sector Undertakings, Chamber of Commerce etc., with PCRA acting as the nodal coordinating agency. Mass awareness and educational programmes and various sectoral activities are undertaken. Inaugural functions are presided over by dignitaries such as Union Ministers, Governors, Chief Ministers, etc. and the Fortnight ends with a Valedictory function in every State.

6.3 END USERS OF PETROLEUM PRODUCTS AND CONSERVATION EFFORTS

In addition to the activities of PCRA detailed above, sectoral conservation steps taken by it are as follows:

TRANSPORT SECTOR

Adoption of practices conducive to increased fuel-efficiency

Training programmes

INDUSTRIAL SECTOR

Replacement of old and inefficient boilers, furnaces and other oil-operated equipment with efficient ones

Promotion of fuel-efficient practices and equipment.

AGRICULTURAL SECTOR

Standardization of fuel-efficient irrigation pumpsets

Rectification of existing pumpsets to make them more energy efficient

HOUSEHOLD SECTOR

Development as well as promotion of the use of fuel-efficient equipment and appliances like kerosene and LPG stoves

Action Group meetings and adoption of States has been introduced to give further impetus to the oil conservation movement and for focussed attention at the State level.

6.4 R&D PROJECTS

(i) RECOVERY OF KEROSENE IN TEXTILE PRINTING

In view of the large-scale losses of kerosene used in the drying section of the textile pigment-printing machine, an R&D project was successfully commissioned to recover kerosene vapors. Under this project at one plant 180 KL of kerosene worth Rs. 14.4 lakhs is being recovered and recycled per annum. The technology developed is being promoted in the textile sector.

(ii) BATTERY OPERATED VEHICLES (BOV’s)

Battery operated vehicles around Taj Mahal area run by Agra Development Authority (ADA) have operated satisfactorily for the last six years leading to a savings in diesel and reduction in pollution. To provide thrust and to promote the operation of BOV’s, PCRA has sponsored two BOV’s to be operated by Airline Authorities at IGI Airport for transportation of passengers from terminal to Aircraft and back as a demonstration project. Moreover, to encourage and support the operation of BOV’s on a larger scale a subsidy of Rs. 1 lakh per BOV is being provided by PCRA, in addition to the subsidy (upto 50% of the cost of vehicle) being provided by MNES.

(iii) SYNCHRONIZATION OF TRAFFIC SIGNALS

A study undertaken at Delhi in 1996 revealed a wastage per day of petrol and diesel of 3 lakh and 1 lakh litres respectively by vehicles while waiting for green signal at the traffic intersections, amounting to a financial loss of Rs. 246 crores per annum. The study brought out a scope for MS & HSD saving by synchronization of traffic signals and reducing the waiting period for the vehicles.

To demonstrate, projects in 5 cities viz. Delhi, Calcutta, Pune, Bangalore and Chennai were taken up for synchronization. Project at Calcutta has since been successfully completed with the result that City and State administration, Traffic Police, PWD etc. are convinced about benefits of synchronization of traffic signals. Projects in other towns are in advanced stage of completion.

6.5 FURTHER TIPS FOR CONSERVATION TO BE TAKEN BY INDIVIDUALS

(A) CONSERVATION AT HOME

Customers are recommended a switchover to Nutan gas stove or Nutan wick stove developed by Indian Oil and aimed at fuel conservation

While cooking use wide bottom vessels with covers

Allow food articles taken out of the refrigerators to attain room temperature before cooking them

Soak cereals and dals for sometime before cooking them to reduce the cooking time as well as the fuel consumption.

Use just sufficient water for cooking

Pressure cookers used with separators lead to substantial fuel saving.

Reduce flame by bringing the burner knob to the simmer position as soon as the water starts boiling

Try to eat together to avoid repeated warming of food. This not only saves fuel but also preserves the nutritional value of food

Light the flame only after all preparations have been made and the vessel is ready to be put on the stove.

Use hot water from solar water heaters for cooking if the facility is available

Try to use a solar cooker, if facility and time permit

In the rural sector, use of gobar gas plants, would be an excellent fuel conservation technique

If feasible, the use of electric hot plates could also be a fuel-saving tip.

(B) KEROSENE FOR ILLUMINATION

Switch-over to Nutan Hurricane Lanterns developed by Indian Oil both for better illumination & fuel conservation is recommendedThe use of electric lamps or solar lanterns, if feasible.

(C) CONSERVATION ON ROADS

The first rule of fuel conservation would be to travel judiciously and curtail wasteful driving

Wherever possible/ available and convenient, use public transport instead of using personal transport

Matching the size of the vehicle to your need would also go a long way in conserving fuel. For instance if you have the option of a personal car and a scooter, then use the scooter when only two persons have to travel, and the car if more persons have to travel or heavy luggage needs to be transported.

Car pooling to work will not only conserve fuel but will also improve social relations with your colleagues

Following traffic signals will help avoid traffic jams and reduce lower gear driving and idling.

As far as possible, avoid idling the vehicle, be it a car, scooter or any other mechanized transport.

The criteria for choosing the vehicle you are going to buy should be its fuel efficiency.

There is no substitute for timely attention, servicing and tuning of the vehicle in fuel conservation and emission control. This should include checking of injectors and spark plugs, correct tyre pressure, re-greasing, topping up or renewal of lubricants for engine and gear boxes.

The use of quality lubricant is extremely important. There should not be any compromise on this aspect.

Correct driving habits are important for conservation. Try to avoid sudden speeding, braking & stopping, clutch riding, idling, over- speeding, and over-loading

Have your vehicle checked for emission control regularly – not only because defaulters are fined, but because it leads to fuel conservation and pollution control, which as citizens of India, is our moral duty. It is time we inculcate these measures to become a part of our daily routines. Only by practising and preaching these conservation tips can we think of future progress. Given the difficult times ahead, it becomes our responsibility to spread this awareness, particularly amongst it the youth who will be citizens of tomorrow. Good habits taught early will salvage the oil shortage to a great extent.

7. ROLE OF OIL INDUSTRY TO PROMOTE OIL CONSERVATION

7.1 Soft loan and subsidies are given by Oil Industry (OIDB) for conducting energy audits, purchase of energy audit equipments/ instruments, upgradation of maintenance facilities at garage, LIP rectification, foot valve replacement, upgradation of testing facilities to foot valve manufacturers for promoting oil conservation.

7.2 The Oil Industry is also promoting the use of alternate sources of energy to the maximum extent possible. Many petrol pumps are provided with SPV system. Some Oil Company colonies have solar water heaters, solar cookers, solar lanterns, gobar gas plants, improved choolhas, efficient kerosene stoves & lanterns. In some select villages in the districts of Solan, Sultanpur and Jaisalmer Wind mills are also being considered. All these will act as stimuli for other to emulate.

Petroleum Conservation, then becomes our joint responsibility be it the industries, individual citizens, organizations, Oil Companies or the Government. Each one of us has a specific and significant role to play.

8. INTER FUEL SUBSTITUTION

8.1 COMPRESSED NATURAL GAS (CNG)

Compressed Natural Gas (CNG) is used as a fuel in transport sector in many countries. It is a safe, clean burning and environment friendly fuel. It has been established that exhaust emissions like hydrocarbons and carbon monoxide are significantly reduced as compared to other fuels. Toxic emissions such as lead and sulphur are completely eliminated. Existing petrol vehicles can use CNG by fitting a conversion kit. The CNG converted vehicles have the flexibility of operating either on petrol or on CNG.

An experimental programme to use CNG as fuel in transport sector in the country was initiated by GAIL in 1992, whereby CNG was made available in Delhi, Mumbai and Baroda. The supply of CNG in Mumbai and Delhi are managed by two joint ventures viz. Mahanagar Gas Nigam Ltd. and Indraprastha Gas Limited respectively and in Surat and Ankleshwar, by a private company. The average cost of converting a petrol car to CNG is about Rs.35,000. There are over 10,000 CNG converted Petrol vehicles in Mumbai and over 3000 such vehicles in Delhi. 11 buses of DTC are running on CNG in Delhi, with 2 existing diesel buses converted to CNG on trial basis.

CNG dispensing retail outlets on mother-daughter concept as well as online dispensing units have been set up in Delhi. Under the former system, Natural Gas is compressed and filled into truck mounted cascades (basket of cylinders) in the mother compressor station and transported to daughter units for dispensing to CNG vehicle. The mother station initially set up in Ghaziabad has been re-located and brought near to Delhi at Sarai Kale Khan, in May’97. At present there are seven daughter and four on-line dispensing retail outlets in Delhi. Further expansion of the infrastructural network to 80 CNG outlets is proposed by March 2000. The process of acquiring land sites to set up the required number of outlets is going on.

8.2 FEASIBILITY OF ETHANOL/METHANOL AS AUTOMOTIVE FUEL

Exploration of the feasibility of using alcohol-blended fuel has also received attention in this Ministry. Recommendations of Technical Committee studying this issue have testified to the safe usage of blended alcohol upto 6% with gasoline which does not require any modification of engine design, the only stipulation being that the alcohol should be of anhydrous variety. Consideration of the use of this fuel is still in progress.

8.3 USE OF LPG AS AUTOMOTIVE FUEL

LPG is recognized as superior fuel to petrol and diesel in terms of the vehicular emissions. To abate pollution caused by vehicles, a number of countries in the World have been using LPG as auto fuel for more than last 30 years.

In India, the use of LPG as auto fuel has been prohibited by Motor Vehicles Act and LPG Control Order, 1974. With the liberalization in the marketing of LPG initiated in 1993 by decanalizing the import of LPG and introduction of parallel marketing of LPG, a number of private sector including multinationals have started making investment in the development of infrastructure for import of LPG and its marketing. The availability of LPG from the public sector as well as private sector has also been increasing through indigenous production as well as imports.

In order to take further actions relating to amendment of the Acts/Rules/Control Order, an Expert Committee was constituted. Taking into account the recommendations of the Committee, the concerned Ministries and Departments are in the process of making necessary amendments.

9. STEPS TAKEN BY THE MINISTRY ON ENVIRONMENTAL ISSUES

9.1 UPGRADATION OF FUEL QUALITY

(A) INTRODUCTION OF UNLEADED PETROL

In pursuance of the need for reduction of environmental pollution due to emissions from vehicles, from April,1995 the Oil Companies have made available unleaded petrol in the in the city of Agra and the four metros of Delhi, Mumbai, Calcutta, Madras and radial routes emanating from these metros. Petrol with reduced lead content of 0.15g/ltr. (maximum) was made available all over the country from December, 1996. The availability of unleaded petrol was extended to Capitals of state and Union Territories by June, 1998 and would be extended to throughout the country by March 2000.

(B) SUPPLY OF LOW SULPHUR HSD

The sulphur in diesel has considerable potential to pollute the air and damage human health, especially with regard to respiratory disorders caused by high level of respirable particulate matter. Hence, Low Sulphur Diesel i.e., containing 0.5% sulphur by weight as against the normal proportion of 1% by weight was supplied w.e.f. April, 1996 in metros and Taj Trapezium. Supply of diesel with still further reduction of sulphur content upto only 0.25% by weight has been envisaged w.e.f. January 2000 in the entire country. It was, however, introduced in Taj Trapezium w.e.f. 1.9.1996 and in Delhi from 14.8.1997. An investment of Rs. 5600 crores has been made to set up a diesel hydro desulphurization plant in the country. A further reduction in the sulphur content to 0.05% in diesel in the National Capital Region w.e.f. April 2000 in compliance of Supreme Court orders to adopt Euro II norms in the country is contemplated in a phased manner.

(C) SPECIFICATION OF 2-T OILS FOR 2-STROKE ENGINES

To address the environmental issues relating to emissions from 2/3 wheelers, Synthetic 2-stroke engine oils meeting JASO, FC, Japan have been introduced w.e.f. 1.4.1999. These environment friendly oils reduce visible smoke and lead to fuel conservation.

(D) RESTRICTIONS IN BENZENE CONTENT

The benzene content in gasoline is to be restricted to a maximum of 3% by volume in metro cities and 5% by volume in other cities as required under the notification of the Central Pollution Control Board from the year 2000. In Delhi, this has already been implemented.>

(E) ADDITIONAL STEPS TAKEN IN DELHI

Pre-mixed dispensers for supply of petrol to 2-stroke engine have been installed at all retail outlets of all Oil Marketing Companies by December 1998 and ban enforced on sale of loose 2T oils at petrol stations and service garages from that date. One Fuel Testing Laboratory (FTL) has been set up at Noida for monitoring fuel adulteration.

9.2 PROTECTION OF TAJ MAHAL

TEN POINT INITIATIVE FOR REDUCTION OF POLLUTION IN TAJ>

In recent years, the impact of air pollution on the Taj Mahal has become a matter of grave concern. It has been recognized that corrosive impact of pollutants and emissions from industries, vehicles, etc. in the vicinity of Taj needs to be addressed first. Keeping this in view, Minister of Petroleum & Natural Gas, has launched a 10 point programme aimed at reducing air pollution for protection of this national monument by introducing cleaner fuels. The progress of implementation of the programme is closely monitored by a task force set up in the Ministry. The point-wise status of implementation of the programme is given below:

(i) LPG FOR ALL HOUSE HOLDS

The entire waiting list for LPG connections in Taj Trapezium area has been cleared and connections are now offered across the counter.

(ii) PREFERENTIAL ALLOCATION OF LPG FOR INDUSTRIES

Under this programme Oil Companies supply LPG to industries and commercial establishment in the Taj Trapezium area on demand.

(iii) SUPPLY OF LEAD FREE PETROL

Unleaded petrol has been made available throughout Agra.

(iv) LOW SULPHUR DIESEL FOR TRANSPORT

Extra Low sulphur Diesel containing 0.25 per cent sulphur is supplied in Taj Trapezium w.e.f. 1.9.1996 and supply of 0.05% Extra Low High Speed Diesel would be put in place shortly.

(v) INTENSIFICATION OF ENVIRONMENT MANAGEMENT BY MATHURA REFINERY

Under this programme, 1 lakh trees have been planted in the vicinity of Taj. Sufficient care has been taken for maintenance. Extension of the target is being considered.

(vi) NATURAL GAS FOR INDUSTRIES

Six lakh cubic metres of natural gas per day has been allocated for supply through pipelines to the industrial units in the area. Pipelines to Agra and Ferozabad are ready. Gas purchase agreements have already been signed with a number of industrial units in Ferozabad and Agra. Out of these units have already started using natural gas and fifty more would do so by Dec. 1999. The distribution of gas would be undertaken by a Joint Venture Company (JVC). Pending formation of JVC, GAIL has been implementing the project for setting up the distribution network in Agra and Ferozabad. However, the progress is conditional on the underpinning of the gas pipeline to the Yamuna River Bridge.

(vii) COMPRESSED NATURAL GAS (CNG) FOR VEHICLES

CNG for transport vehicles would be introduced in Agra City after the issue of the gas pipeline support across the Yamuna Bridge is resolved. The identification of sites for CNG facilities is in progress.

(viii) CLEAN FUEL FOR MATHURA REFINERY