Tool maintenance

Tool maintenance procedure

The purpose of the procedure is to provide process guidelines for maintenance, tool identification, storage and preventive maintenance of tool.

The tool maintenance procedure is implementing by maintenance management to enhancement of productivity, reliability of tools, and efficiency of related engineers managed tool maintenance activities. The tool maintenance procedure is provides the structural guidelines to be followed for all tooling related maintenance, tool identification, storage of tools and preventive maintenance activities. The procedure should be applicable to all the storage areas of tools, maintenance and production line where used the tools. In the preventive maintenance related activities, identification of concern of tools should be managed by design engineers and maintenance team.

For the maintenance activities, each tools should be identify and managed as per required category as per its condition, based on the tool condition tool maintenance will put the specific labels or sign to easier for identified category by storage department, the designed areas should be maintained and stacked tools as its defined and accepted category. There are simply maintained color codes and specific numbers that easier for identify ready tool or current tools, under preventive maintenance tools and obsolete tools which are no long in use or damage condition. The design engineer is responsible for define tool identification for each tool, and it should be unique number. In case any tools are customers or third party property that should be indicated specific color or unique number to easier for identification and tracking each one, during any operation in case any tool damages or loss, the customer informed by concern authority and appropriate action managed accordingly. There is important for the tooling storage for the maintaining properly by stored in the specific rack as designed for maintain tools with proper racking system and index for easy identification, stacking and retrieving at appropriate locations of storage, the tools are properly preserved and monitored by related employee timely.

The tool maintenance procedure is conducted by general ways as machinery, equipment and other activities are conducted, the general flow of tool maintenance is conducted by concern engineers for comply the maintenance requirements for tool. The tool maintenance conducted as real time maintenance called break down maintenance and preventive maintenance. In the breakdown maintenance activities conducted when tool problems occurred during the production shall be recorded in register by concern supervisor and needs to communicated to tool room / store room for correction specific identification labels.

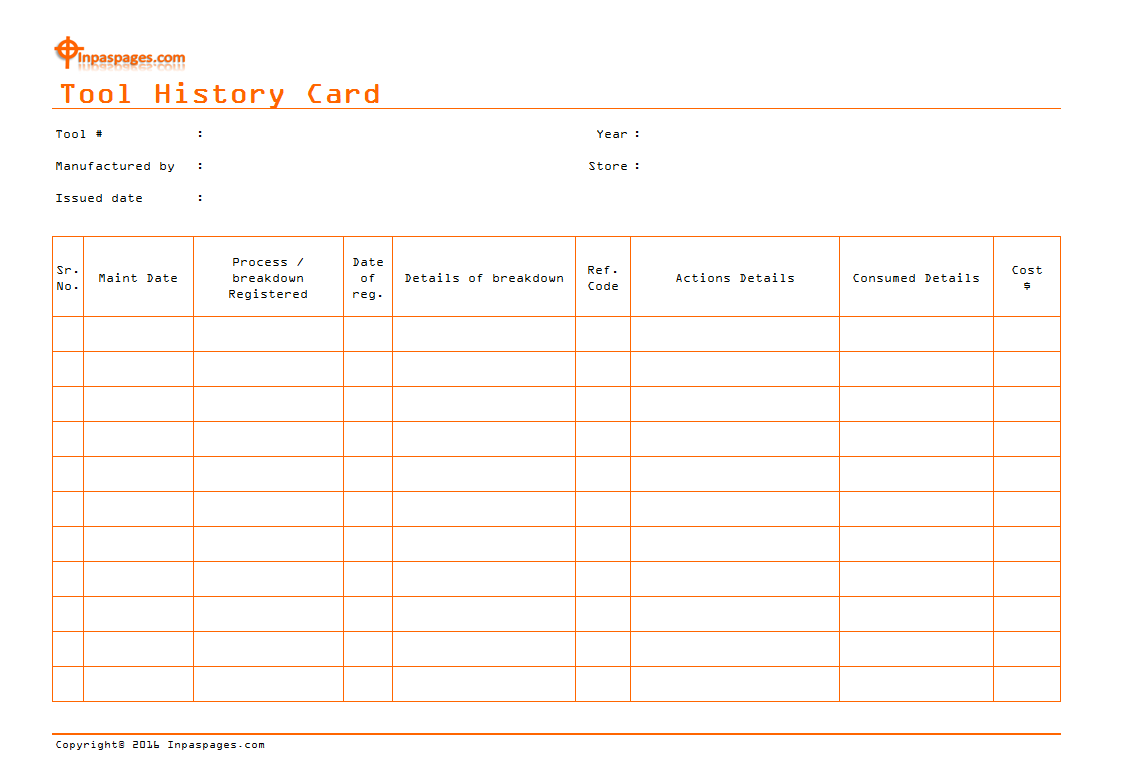

The preventive maintenance activities are managed as per scheduled by maintenance manager or as per concern department supervisor communicated for conducting preventive maintenance in rear cases. The store room supervisor should correct the tool and details recorded in the registers, hence the preventive maintenance records are maintained as per scheduled and checklist filled by maintenance engineers. On after correction of tool maintenance needs to maintain records on acceptance of concern department head, hence in preventive maintenance reporting and records are maintained in the history card format by acceptance sign of concern department head. See picture below provided for education purpose only(inpaspages.com):