Boosting Ammonia Plant Performance - Heat Exchanger Updating

Heat exchangers make up the largest number of equipment items for older as well as modern Ammonia plants. Each heat exchanger service in the plant performs an important role, which may include Process Gas Heating and Cooling, Gas Compression Heat Recovery, Process Waste Heat Recovery, Steam Generation, Boiler Water Heating, Reactor Preheat and Reaction Heat Recovery, Process Gas Chilling with Product Condensing, Gas Cooling with Steam Condensing, Steam Turbine Exhaust Condensing, Vapor-Liquid Separation Column Reboiling, Solvent Heating and Cooling, Lube Oil Cooling and Refrigerant Vapor Condensing.

The vast numbers of Ammonia plants in North America were built 25-35 years ago, at a time when the price of energy was less than one third of modern energy cost. Thus, the original technical design basis for older plant equipment, including heat exchangers, permits some substantial opportunities for improvements in efficiency and capacity when individual items of heat exchanger equipment develop failures, demanding replacement for maintaining plant operation. New designs for replacement heat exchangers add lasting value to the plant operation through reduced gas pressure loss, higher throughput for given pressure loss, greater heat transfer or sometimes combinations of these benefits, reducing production costs. Sometimes

plants prefer to stick with what has worked well over many years, including some improved features into replacement equipment, while at other times, historic equipment performance dictates the need for improved designs with specific features to replace older equipment concepts to overcome reliability or deteriorating performance issues.

![]()

High Pressure Waste Heat Boilers

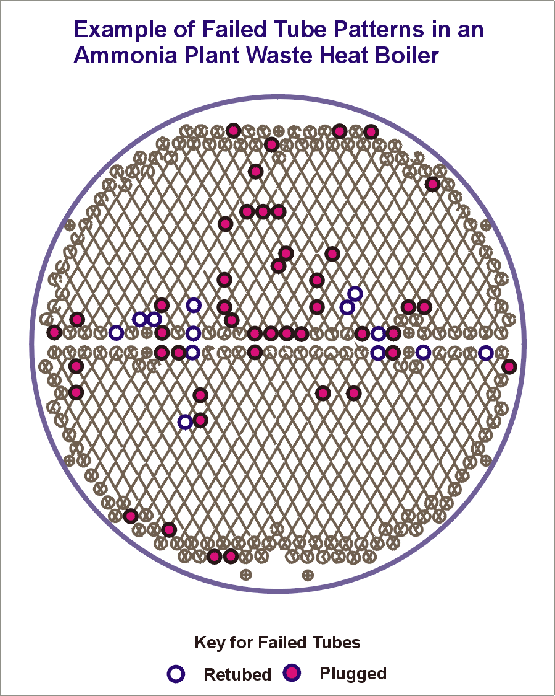

Certain designs of vertical process gas waste heat recovery boilers have had problems with corrosion

failure of tubes when the shell side fluid is boiler feedwater at failure regions near the tubesheets.

Accumulation of corrosion damage is slow in early life of the equipment, but accelerates after about 10-15

years of service for such exchangers, often mounting to

multiple failures per year, each involving a temporary

repair outage. Retubing or plugging when failures begin

to mount is time consuming and difficult and is generally

is done in the field, because the equipment is

welded-in, connecting to other equipment, such as

water-jacketed transfer lines and boiler high pressure

steam system piping. A permanent solution that has

proven successful for more than a decade is to replace

the waste heat boiler with a new design with boiler

feedwater arranged up-flow in the tubes to eliminate

the possibility of trapping corrosive boiler dissolved

solids on the outside of tubes in the lower region of the

bundle shell side. The cost of such retrofits can be

similar to or only modestly greater than replacement of

the exchanger in-kind. When historic costs for outages,

repairs and lost production are weighed, such new

designs have strong economic advantages.

Process Gas Feed/Effluent Exchangers

In most Ammonia process designs, heating and cooling of synthesis gas streams is accomplished by reactor effluent being

used for heating reactor feed, recovering a substantial part of exothermic reaction heat. Examples of such heat exchanger

equipment include Methanation and Ammonia Synthesis feed heating. When plants are expanded in capacity, these

exchanger services often become a reliability problem because of tube leaks from failures caused by shell side induced tube

vibration, resulting in wear from contact with adjacent tubes or shell baffles. Generally the plant contractor designs

exchangers for modest increased capacity to maximize contract profits. Shell side gas velocities induce tube vibration and

develop into tube leaks when plant rates are pushed typically beyond 20-40% higher production through incremental

expansion projects. It is not always clear why these exchangers initially begin to fail because the expansion projects are

generally spread out over several years. Usually such tube failures do not show up in any consistent pattern, but instead are

spread out rather uniformly throughout the tube bundle. Time is not so much the cause of these failures, but instead, plant

rate is the key initiator. Plugging tubes in brief repair outages will buy time to confirm vibration as the failure mechanism and

slightly curtailing plant rate can reduce the frequency of these tube leaks. Sophisticated heat exchanger design and rating

software can identify key parameters that indicate likelihood of vibration induced tube leaks, including tube span, crossflow

velocity, critical velocity, fluid flow-energy (Density times Velocity squared), vortex shedding frequency, Strouhal number,

frequency ratio, turbulent buffeting frequency, baffle and collision damage numbers and other related paramete

![]()

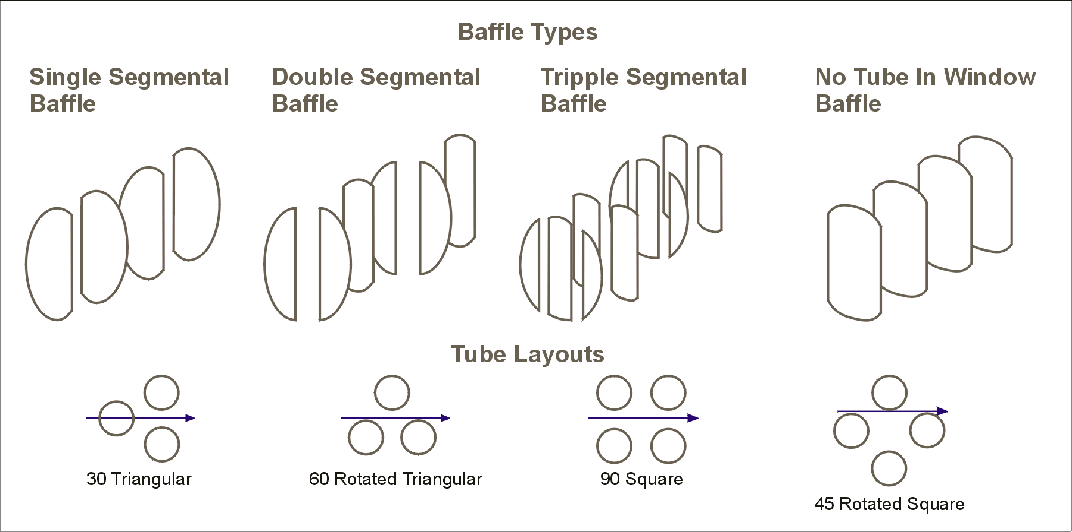

For heat exchangers where vibration damage is indicated from inspection (pulled tubes have long external wear patterns or

baffle notches), replacement equipment procurement should be seriously considered to maintain high on-stream time. New

designs to replace damaged heat exchangers should examine higher (existing and future) plant capacity as a design basis

and/or include means of "stiffening" the tube bundle, such as NTIW (no tubes in windows) baffles to shorten the unsupported

tube span, use of thicker baffles or tighter tube/baffle clearances and consider other improvements such as changing baffle or

shell type, the use of impingement plates, increasing the drop under shell side nozzles or changing tube thickness, tube pitch

or tube orientation.

Hot Process Gas Exchangers with Hydrogen

Typical examples of such heat exchanger services include High Temperature Shift Converter Eflluent, Methanator Effluent or

Ammonia Synthesis Reactor coolers. Often hydrogen attacks the tube-tubesheet weld joint, resulting in cracks which can

further propagate into the tubesheet. If the tubesheet includes a layer of cladding material of higher alloys (Inconel, Incoloy

or similar materials) this improvement can result in better resistance to cracking and also lends to easier welding repair and

greater durability for crack repairs in welded tube to tubesheet joints, should such failures occur.

![]()

Heat exchangers make up the largest number of equipment items for older as well as modern Ammonia plants. Each heat exchanger service in the plant performs an important role, which may include Process Gas Heating and Cooling, Gas Compression Heat Recovery, Process Waste Heat Recovery, Steam Generation, Boiler Water Heating, Reactor Preheat and Reaction Heat Recovery, Process Gas Chilling with Product Condensing, Gas Cooling with Steam Condensing, Steam Turbine Exhaust Condensing, Vapor-Liquid Separation Column Reboiling, Solvent Heating and Cooling, Lube Oil Cooling and Refrigerant Vapor Condensing.

The vast numbers of Ammonia plants in North America were built 25-35 years ago, at a time when the price of energy was less than one third of modern energy cost. Thus, the original technical design basis for older plant equipment, including heat exchangers, permits some substantial opportunities for improvements in efficiency and capacity when individual items of heat exchanger equipment develop failures, demanding replacement for maintaining plant operation. New designs for replacement heat exchangers add lasting value to the plant operation through reduced gas pressure loss, higher throughput for given pressure loss, greater heat transfer or sometimes combinations of these benefits, reducing production costs. Sometimes

plants prefer to stick with what has worked well over many years, including some improved features into replacement equipment, while at other times, historic equipment performance dictates the need for improved designs with specific features to replace older equipment concepts to overcome reliability or deteriorating performance issues.

High Pressure Waste Heat Boilers

Certain designs of vertical process gas waste heat recovery boilers have had problems with corrosion

failure of tubes when the shell side fluid is boiler feedwater at failure regions near the tubesheets.

Accumulation of corrosion damage is slow in early life of the equipment, but accelerates after about 10-15

years of service for such exchangers, often mounting to

multiple failures per year, each involving a temporary

repair outage. Retubing or plugging when failures begin

to mount is time consuming and difficult and is generally

is done in the field, because the equipment is

welded-in, connecting to other equipment, such as

water-jacketed transfer lines and boiler high pressure

steam system piping. A permanent solution that has

proven successful for more than a decade is to replace

the waste heat boiler with a new design with boiler

feedwater arranged up-flow in the tubes to eliminate

the possibility of trapping corrosive boiler dissolved

solids on the outside of tubes in the lower region of the

bundle shell side. The cost of such retrofits can be

similar to or only modestly greater than replacement of

the exchanger in-kind. When historic costs for outages,

repairs and lost production are weighed, such new

designs have strong economic advantages.

Process Gas Feed/Effluent Exchangers

In most Ammonia process designs, heating and cooling of synthesis gas streams is accomplished by reactor effluent being

used for heating reactor feed, recovering a substantial part of exothermic reaction heat. Examples of such heat exchanger

equipment include Methanation and Ammonia Synthesis feed heating. When plants are expanded in capacity, these

exchanger services often become a reliability problem because of tube leaks from failures caused by shell side induced tube

vibration, resulting in wear from contact with adjacent tubes or shell baffles. Generally the plant contractor designs

exchangers for modest increased capacity to maximize contract profits. Shell side gas velocities induce tube vibration and

develop into tube leaks when plant rates are pushed typically beyond 20-40% higher production through incremental

expansion projects. It is not always clear why these exchangers initially begin to fail because the expansion projects are

generally spread out over several years. Usually such tube failures do not show up in any consistent pattern, but instead are

spread out rather uniformly throughout the tube bundle. Time is not so much the cause of these failures, but instead, plant

rate is the key initiator. Plugging tubes in brief repair outages will buy time to confirm vibration as the failure mechanism and

slightly curtailing plant rate can reduce the frequency of these tube leaks. Sophisticated heat exchanger design and rating

software can identify key parameters that indicate likelihood of vibration induced tube leaks, including tube span, crossflow

velocity, critical velocity, fluid flow-energy (Density times Velocity squared), vortex shedding frequency, Strouhal number,

frequency ratio, turbulent buffeting frequency, baffle and collision damage numbers and other related paramete

For heat exchangers where vibration damage is indicated from inspection (pulled tubes have long external wear patterns or

baffle notches), replacement equipment procurement should be seriously considered to maintain high on-stream time. New

designs to replace damaged heat exchangers should examine higher (existing and future) plant capacity as a design basis

and/or include means of "stiffening" the tube bundle, such as NTIW (no tubes in windows) baffles to shorten the unsupported

tube span, use of thicker baffles or tighter tube/baffle clearances and consider other improvements such as changing baffle or

shell type, the use of impingement plates, increasing the drop under shell side nozzles or changing tube thickness, tube pitch

or tube orientation.

Hot Process Gas Exchangers with Hydrogen

Typical examples of such heat exchanger services include High Temperature Shift Converter Eflluent, Methanator Effluent or

Ammonia Synthesis Reactor coolers. Often hydrogen attacks the tube-tubesheet weld joint, resulting in cracks which can

further propagate into the tubesheet. If the tubesheet includes a layer of cladding material of higher alloys (Inconel, Incoloy

or similar materials) this improvement can result in better resistance to cracking and also lends to easier welding repair and

greater durability for crack repairs in welded tube to tubesheet joints, should such failures occur.

| Compressor Intercoolers Compressors need inter-stage heat recovery to maximize capacity while minimizing head and power requirements in the pumping of gases through process equipment. Lower compressor inter-cooler pressure drop translates into decreased energy consumption for the compressor when upgrading with improved heat exchanger designs. Well designed compressor intercoolers can have a useful life of 10-20 years, but occasionally failures result from higher loads caused by gradual plant expansion. Additional operating problems also develop, such as reduced intercooling from fouling, generally from the cooling water side or mechanical leaks through the tubes or at tube-tubesheet joints, resulting in gas loss into the cooling water. In certain low gas pressure intercooler applications failures causing leaks may result in cooling water entering the compressor with the gas, resulting in damage to interstage seals and deteriorating compressor efficiency and capacity. In instances of such leakage, contamination can become a critical problem, since suspended and dissolved solids from cooling water pass into the compressor and build up or result in other problems. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| When redesigning exchangers, changing TEMA Shell types can provide cost efficient solutions for achieving reduced intercooler gas pressure losses and energy savings. For example, TEMA X cross-flow designs can provide extremely low pressure drop performance at lower performance based cost compared with the more commonly used TEMA E, F and J shell types. In the application of cross-flow intercoolers, careful attention must be given to proper design of seal strips and dummy tubes in partition spaces in multi-tube pass configurations to prevent shell side fluid bundle bypassing, which could otherwise impact on thermal performance. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||